2022 Wholesale Price Lug Body Butterfly Valve – Lug Type Butterfly Valve with Body – Zhongfa

2022 Wholesale Price Lug Body Butterfly Valve – Lug Type Butterfly Valve with Body – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1600 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

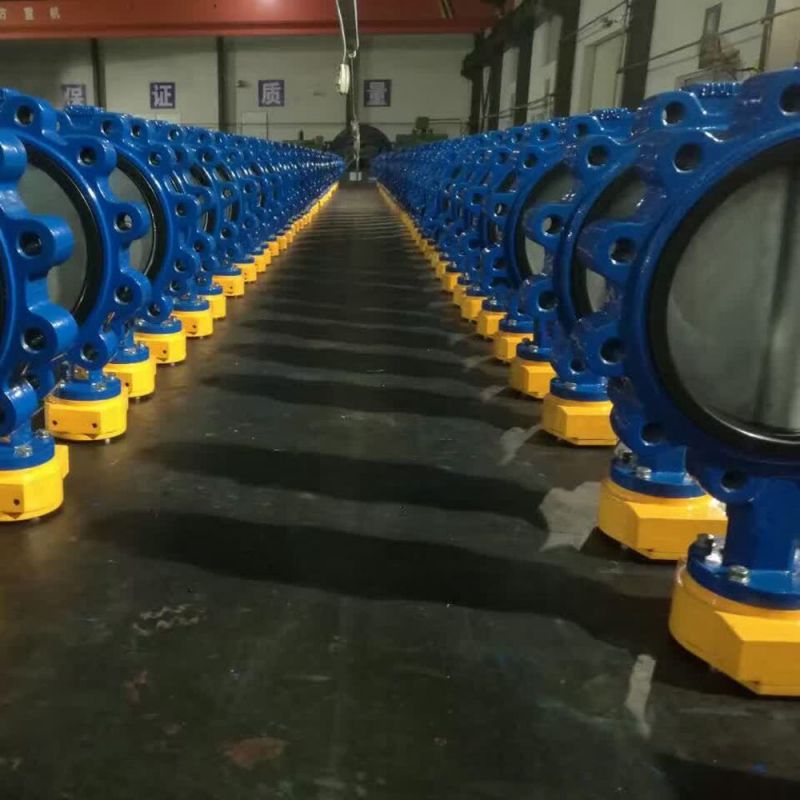

Product Display

Product Advantage

General purpose lug butterfly valve manufactured according to EN 593. Wide range of standard materials available for various applications.

The tongue and groove seat design locks the seat in place and gives the butterfly valve dead end capability

ZFA valves are pressure tested at 110% rated pressure to ensure bubble free closure.

ZFA butterfly valves are pinless design.

Chemical, weather, abrasion and impact resistant coatings.

The flanged butterfly valve disc has two-way bearings, good sealing and no leakage during pressure test.

The flow curve tends to be straight. Excellent adjustment performance.

Center plate structure, small opening and closing torque

Long service elevator. Withstand the test of thousands of openings and closing operations.

Seat test: water at 1.1 times the working pressure.

Functional/Operational Test: At final inspection, each valve and its actuator (flow lever/gear/pneumatic actuator) undergo a complete operational test (open/close). The test is performed without pressure and at ambient temperature. It ensures proper operation of the valve/actuator assembly, including accessories such as solenoid valves, limit switches, air filter regulators, and more.

The lug valve is mainly used for pipeline flow, pressure and temperature control in various industrial automation production, such as: electric power, petrochemical, metallurgy, environmental protection, energy management, fire protection system and butterfly valve sales.

At the same time, the lug valve has good fluid control performance and is easy to operate.

They are not only widely used in general industries such as petroleum, gas, chemical, water treatment, etc., but also in the cooling water system of thermal power plants.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for 2022 Wholesale Price Lug Body Butterfly Valve – Lug Type Butterfly Valve with Body – Zhongfa , The product will supply to all over the world, such as: California, Czech, Bhutan, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.