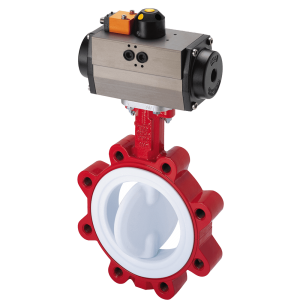

"Pneumatic" refers to the actuation mechanism, which uses compressed air to operate the valve, enabling remote or automated control.

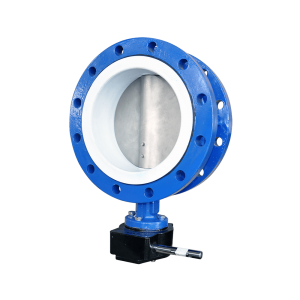

A flanged butterfly valve is one type of connection type, featuring integral flanges on both ends of the valve body, allowing for secure bolted connections to pipe flanges.

Cast iron and ductile iron butterfly valves are widely used for flow control in various industries, but they differ in material properties, performance, cost and applications.

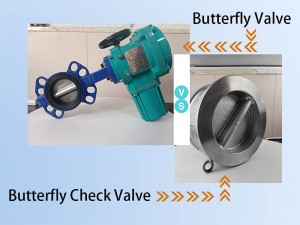

What is the difference between a butterfly valve and a butterfly check valve? While they share similar names and both utilize a disc-type design, their functions, operations, and applications are quite different.

Pneumatic butterfly valves, with their simple design, fast operation, and cost-effectiveness, have become an indispensable component of modern piping systems.

This standard is published by the BSI and aligns with European standards (EN), providing a comprehensive framework for the design, materials, dimensions, testing, and performance of butterfly valves.

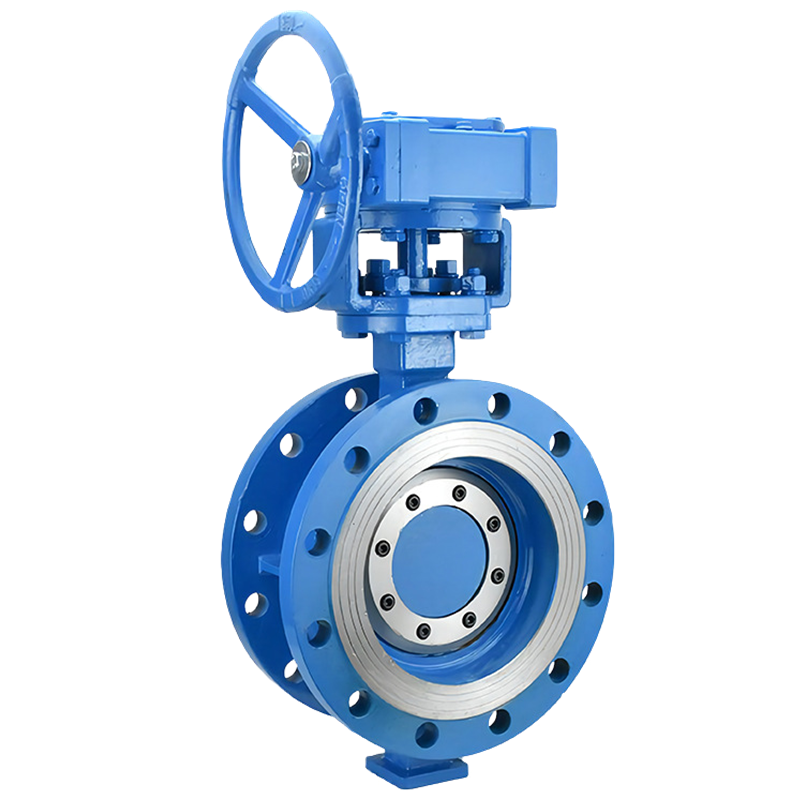

This article explores the key differences, advantages, disadvantages, and applications of lug and double flange butterfly valves to guide your decision-making process.

- Exhibition: Industrial Valve Exhibition

- Location: Centro Citibanamex

- Stand Number: A231

- Date: 2-4, Sep

• Event: ECWATECH 2025

• Dates: September 9–11, 2025

• Booth: 8C8.6

• Venue: Crocus Expo International Exhibition Centre, Moscow, Russia

A summary of the diameter range of butterfly valves with different connection methods and structural types, based on common industry standards and application practices. Since the specific diameter range may vary depending on the manufacturer and application scenario (such as pressure level, medium type, etc.), this article provides data for zfa valves.

A butterfly valve is a quarter-turn valve. It is used to regulate or isolate fluid flow in pipelines. Butterfly valve and because of its simple design and efficient performance and by all walks of life.

The origin of the name of butterfly valve: the valve flap is shaped like a butterfly and so named.

Among the different types of butterfly valves, high performance butterfly valves (HPBV) and concentric butterfly valves are the two most common designs. This comparison will break down the differences between the two from multiple dimensions to clarify their roles in industrial and municipal applications.

Butterfly valve leakage, solving these problems requires a combination of selecting the right valve, careful installation, regular maintenance, and system optimization. By selecting materials suitable for the application, following installation guidelines and monitoring operating conditions, users can significantly reduce the risk of leakage.

Different types of valve seat materials have different physical and chemical properties and are suitable for various working conditions. In this article, we mainly study and compare the main types, performance and applications of elastic valve seats.

In this article, we will review the top 7 soft-seat butterfly valve manufacturers in China and conduct a detailed analysis from the aspects of certification and qualifications, product quality, production capacity and delivery, price competitiveness, technical capabilities, after-sales service, and market reputation.

In-depth analysis of the differences between API 607 and API 608 standards, mastering the core technical points of industrial valve selection, including the latest testing requirements and compliance guidelines.

A butterfly valve is a device that regulates the flow in a pipe. It is controlled by rotating the disc a quarter turn. They are usually used in applications where they close quickly.

It is well known that butterfly valves are highly efficient, compact in design and cost-effective, so they are widely used in various industries. However, like any mechanical component, butterfly valves can also fail. Failures are divided into congenital and acquired.

There are obvious differences between the category A butterfly valve and category B butterfly valve in structure. Category A butterfly valves are "concentric" type, category B butterfly valves are “offset” type.

Replacing the rubber seals on butterfly valves is a complex process that requires technical knowledge, precision, and the right tools to ensure the valve's functionality and sealing integrity remain intact. This in-depth guide for valve maintenance professionals and technicians provides detailed instructions, best practices, and troubleshooting tips.

We are pleased to announce that our company will be showcasing our latest products and innovations at the prestigious R22, FENASAN exhibition, which will be held from October 22 to October 24, 2024.

The weight of a butterfly valve is critical to the overall design of a system. It affects installation, maintenance, and overall system efficiency. Known for its compact design and efficient flow control.

High-performance butterfly valves enhance the vital role butterfly valves play in industrial applications. These valves can effectively control the flow of fluids.

We sincerely extend a warm invitation to you to attend the upcoming WASTETECH/ECWATECH exhibition, in 8E8.2 IEC Crocus Expo, Moscow on 10-12 September, 2024.

Understand how butterfly valves control fluid flow with a rotating disc. Explore ZFA's cost-effective, low-maintenance solutions for large fluid systems.

The butterfly valve' basic function is to connect or cut off the circulation of the pipeline medium, change the flow direction of the medium, adjust the pressure and flow of the medium, and set various valves, large and small, in the system. Knowing how to measure butterfly valve size can prevent operational inefficiencies and costly mistakes.

The installation process of the butterfly valve involves several key steps. Cleaning before installation, proper alignment, fixing and final inspection ensure optimal performance.

The installation process of the butterfly valve involves several key steps. Cleaning before installation, proper alignment, fixing and final inspection ensure optimal performance.

These companies at the south is concentrated in Jiangsu, Zhejiang, Shanghai regions, mainly producing hard-sealed gate valves, while the north is concentrated in Beijing, Tianjin, Hebei regions, mainly producing soft-sealed gate valves.

This article will introduce the different types of check valves and the considerations for their installation directions in detail.

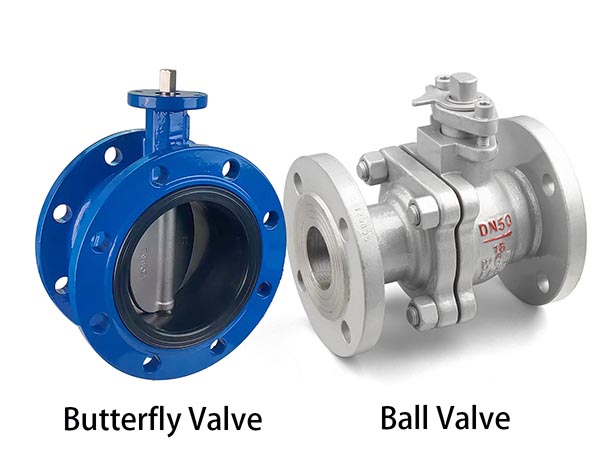

In this comprehensive comparison, we will take a deep look at the design, advantages, disadvantages and applications of these two valves.

This article will discuss the differences between butterfly valves and gate valves in detail from the aspects of principle, composition, cost, durability, flow regulation, installation and maintenance.

if the pipe clearance is limited and the pressure is low, DN≤2000, we recommend wafer butterfly valve; If the pipe clearance is sufficient and the pressure is medium or low, DN≤3000, flange butterfly valve is recommended.

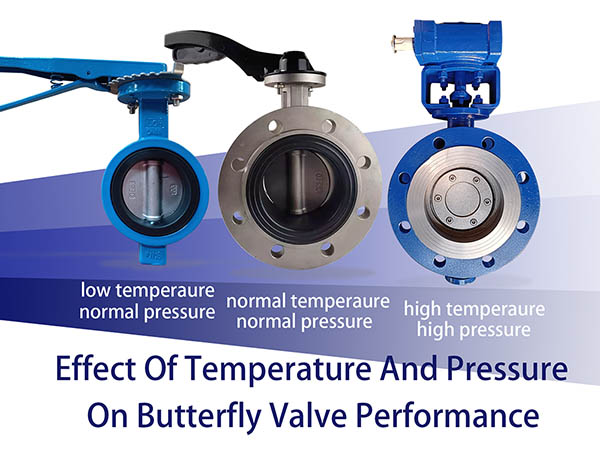

If the temperature is particularly high and there are no large particles, you can choose an all-metal hard-sealed butterfly valve. Otherwise, please choose a lower-priced multi-layer sealing butterfly valve.

In this article, we will delve into the concept of the maximum pressure rating that a butterfly valve can withstand, and study the impact on the rated pressure from aspects such as butterfly valve design, material, sealing, etc.

If the temperature is particularly high and there are no large particles, you can choose an all-metal hard-sealed butterfly valve. Otherwise, please choose a lower-priced multi-layer sealing butterfly valve.

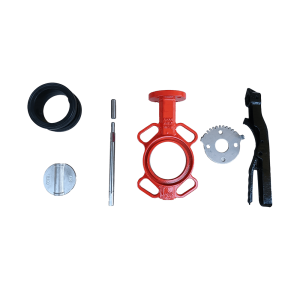

The assembly process of a butterfly valve is a simple yet complex process. Only when each step is performed carefully can the butterfly valve operate normally. The following is a brief description of the wafer butterfly valve assembly process.

Butterfly valve maintenance repairs may vary depending on the type of damage or failure. It can be divided into maintenance, general repair and heavy repair.

The opening and closing time of the butterfly valve is related to the action speed of the actuator, fluid pressure and other factors.

t=(90/ω)*60,

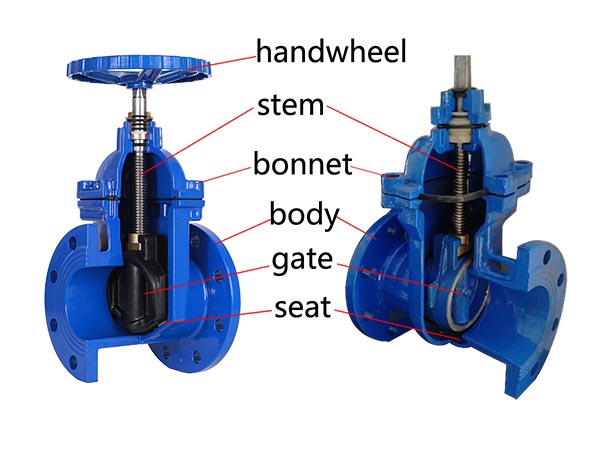

A gate valve is a valve used to OPEN and SHUT-OFF the flow of fluid in a pipeline. It opens or closes the valve by lifting the gate to allow or restrict the flow of fluid. It should be emphasized that the gate valve cannot be used for flow regulation.

There’re many types of butterfly valve disc according to the usage of the butterfly valves, the most common sizes of butterfly valve for stocks are from DN50-DN600, so we’ll introduce the valve discs according to the sizes regularly used.

What are the differences, advantages and disadvantages of butterfly valve and ball valve? In this article, we analyze it from the aspects of structure, principle, scope of use and sealing.

China's valve industry has always been one of the world's leading industries. In this huge market, which companies stand out and become the top ten in China's valve industry?

It mainly depends on the level of silencing. Silencing check valves only eliminate noise and reduce noise. Silent check valves can directly shield and silence the sound when used.

test pressure > nominal pressure > design pressure > working pressure.

The working principle of the electric butterfly valve is to drive the transmission device through the motor to rotate the valve plate, thereby changing the channel area of the fluid in the valve body and control the flow.

According to investigation and analysis, corrosion is one of the important factors causing damage to butterfly valves.

Therefore, the surface coating treatment of the valve body and valve plate is the most cost-effective protection method against corrosion in the external environment.

Hard seals are made of metal, such as metal gaskets, metal rings, etc., and sealing is achieved through friction between metals. Soft seals are made of elastic materials, such as rubber, PTFE, etc.

More and more Chinese valves are exported to various countries around the world, and then a lot of foreign customers do not understand the significance of China's valve number, today we will take you to a specific understanding,hope can help our customers.

Choosing between these two types of butterfly valves depends on the specific requirements of the application, including space constraints, pressure requirements, frequency of maintenance, and budget considerations

According to the flange connection form, the butterfly valve body is mainly divided into: wafer type A, wafer type LT, single flange, double flange, U type flange.

Wafer type A is non-threaded hole connection, LT type 24" above large specifications usually use better strength U-type valve body to do threaded connection, the end of the pipeline needs to use LT type.

The V-shaped ball valve is features a V-shaped port on one side of the hemispherical valve core.

The flow channel opening of O-shaped ball valve is round, its flow resistance is small, and the switching speed is fast.

In the previous article, we talked about gate and globe valves, today we move on to butterfly valves and check valves, which are commonly used in water treatment.

The valve is the control device of the fluid pipeline. Its basic function is to connect or cut off the circulation of the pipeline medium, change the flow direction of the medium, adjust the pressure and flow of the medium, and set various valves, large and small, in the system. An important guarantee for the normal operation of the pipe and equipment.

The control valve flow coefficients (Cv, Kv and C) of different unit systems are control valves under a fixed differential pressure, the volume of water circulating in a unit of time when the control valve is fully open, Cv, Kv and C there is a relationship between Cv = 1.156Kv, Cv = 1.167C. This article shares the definition, unit, conversion and exhaustive derivation process of Cv, Kv and C.

Valve seat is a removable part inside the valve, the main role is to support the valve plate fully open or fully closed, and constitute the sealing vice. Usually, the diameter of the seat is the size of the valve caliber. Butterfly valve seat material is very wide, commonly used materials are soft sealing EPDM, NBR, PTFE, and metal hard sealing carbide material. Next we will introduce one by one...

Check valve refers to the opening and closing parts for the round valve and rely on their own weight and media pressure to produce action to block the medium backflow of a valve. Check valve is an automatic valve, also known as check valve, one-way valve, non-return valve or isolation valve.

Wafer check valves are also known as backflow valves, backstop valves, and backpressure valves. These kinds of valves are automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, belonging to a kind of automatic valve.

Butterfly valve because of its smaller size and simple structure, has become one of the most commonly used valves in the industry, more and more are applied to hydroelectric power, irrigation, building water supply and drainage, municipal engineering and other piping systems, used to cut off or mediate the flow of circulating media flow to use. Then the butterfly valve in the use of the problems that need attention and solutions to what, today we will be specific to understand.

Soft seal gate valves and hard seal gate valves are commonly used devices for regulating and intercepting flow, both have good sealing performance, a wide range of use, and are one of the products that customers purchase more. Some purchasing novices may be curious, the same as the gate valve, what is the specific difference between them

AWWA standard is The American Water Works Association first published consensus documents in 1908. Today, there are more than 190 AWWA Standards. From source to storage, from treatment to distribution, AWWA Standards cover the products and processes related to all areas of water treatment and supply. AWWA C504 is of the typical representative, it is is a kind of rubble seat butterfly valve

The big-size butterfly valves usually refer to butterfly valves with a diameter larger than DN500, usually connected by flanges, wafers. There are two kinds of large-diameter butterfly valves: concentric butterfly valve and eccentric butterfly valves.

The three eccentricities of the Triple Eccentric Butterfly Valve are refer to:

The first eccentricity: the valve shaft is located behind the valve plate,allowing the sealing Ring to closely surround the entire seat in contact.

The second eccentricity: the spindle is laterally offset from the center line of the valve body, which prevents interference with the opening and closing of the valve.

Third eccentricity: the seat is offset from the centre line of the valve shaft, which eliminates friction between the disc and seat during closing and opening.

The double eccentric butterfly valve is named after its two eccentric structures. So what is the double eccentric structure like?

The so-called double eccentric, the first eccentric refers to the valve shaft being off the center of the sealing surface, which means the stem is behind the valve plate face. This eccentricity makes the contact surface of both the valve plate and the valve seat a sealing surface, which fundamentally overcomes the inherent deficiencies that exist in concentric butterfly valves, thus eliminating the possibility of internal leakage at the upper and lower intersection between the valve shaft and valve seat.

Butterfly valve, also called flap valve, is a simple structure of the adjustment valve, that can be used in low pressure pipelines to shut off flow. Rotating around the valve shaft to achieve open and close a valve.

According to the different connection forms, it can be divided into wafer butterfly valve, lug butterfly valve, flange butterfly valve, welded butterfly valve, screw thread butterfly valve, clamp butterfly valve, and so on. Among the most commonly used connection forms are the wafer butterfly valve and lug butterfly valve.

The pneumatic butterfly valve is composed of a pneumatic actuator and a butterfly valve. Air actuated butterfly valve uses compressed air as the power source to drive the valve stem and control the rotation of the disc around the shaft to open and close the valve.

According to the pneumatic device can be divided into single-acting pneumatic butterfly valve and double-acting pneumatic butterfly valve.

Zhongfa Valve is a professional manufacturer of butterfly valve parts and butterfly valves, established in 2006, providing valves and butterfly valve parts products to more than 20 countries in the world, next, Zhongfa Valve will launch a detailed introduction of butterfly valve parts.

Butterfly valves are a family of quarter-turn rotational motion valves used in pipelines, they are usually classified by construction and connection. ZFA is one of the famous wafer butterfly valve manufacturers, flange butterfly valve manufacturers, and lug butterfly valve manufacturers in China.

Types by Connection, they are four types.

ZFA Valve's electric butterfly valves are divided into the following two categories: centerline butterfly valves and eccentric butterfly valves, among which centerline butterfly valves are further divided into wafer butterfly valves, lug butterfly valves and flange butterfly valves.

Electric butterfly valves are assembled from butterfly valves and electric devices. It is widely used in petroleum, chemical, electric power, metallurgy, food, pharmaceutical, textile, paper and other industries. The medium are usually natural gas, air, steam, water, seawater and oil. Motor operated butterfly valves are used to regulate the flow and cut off the medium on industrial pipelines.

We can provide the following kinds of API609 butterfly valves:

According to the connection, we have double-flange butterfly valve, wafer butterfly valve and lug butterfly valve;

According to the material, we can provide ductile iron material, carbon steel material, stainless steel material, brass material, super duplex steel material;

According to the process, we can provide API609 butterfly valve with casting body and welding body.

PTFE Lining Valve also known as fluorine plastic lined corrosion resistant valves, are fluorine plastic molded into the inner wall of the steel or iron valve bearing parts or the outer surface of the valve inner parts. Fluorine plastics here mainly include: PTFE, PFA, FEP and others. FEP lined butterfly, teflon coated butterfly valve and FEP lined butterfly valve are usually used in strong corrosive media.

Our wafer butterfly valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on. Size DN40-DN1200, nominal pressure: 0.1Mpa~2.5Mpa, suitable temperature: -30℃ to 200℃.

We mainly export to totally 22 countries like US, Russia, Canada, Spain etc.

n terms of material, stainless steel butterfly valves are available in SS304, SS316, SS304L, SS316L, SS2205, SS2507, SS410, SS431, SS416, SS201, In terms of structure, stainless steel butterfly valves are available in centric and eccentric lines. Centric line stainless steel butterfly valves are generally made of stainless steel for the valve body, valve plate, and shaft, and EPDM or NBR for the valve seat, They are mainly designed for flow control and regulation of corrosive media, especially various strong acids, such as sulphuric acid and aqua regia.