Butterfly valves and gate valves are two types of valves commonly used in industrial and municipal water conservancy applications. They have obvious differences in structure, function and application. This article will discuss the differences between butterfly valves and gate valves in detail from the aspects of principle, composition, cost, durability, flow regulation, installation and maintenance.

1. Principle

Principle of Butterfly Valve

The biggest feature of butterfly valve is its simple structure and compact design. Its working principle is that the circular butterfly plate rotates around the valve stem as the central axis to control the flow of fluid. The valve plate is like a checkpoint, and only with the consent of the butterfly plate can it pass. When the butterfly plate is parallel to the direction of fluid flow, the valve is fully open; when the butterfly plate is perpendicular to the direction of fluid flow, the valve is fully closed. The opening and closing time of the butterfly valve is very short, because it only needs 90 degrees of rotation to complete the full opening or closing operation. This is also the reason why it is a rotary valve and a quarter-turn valve.

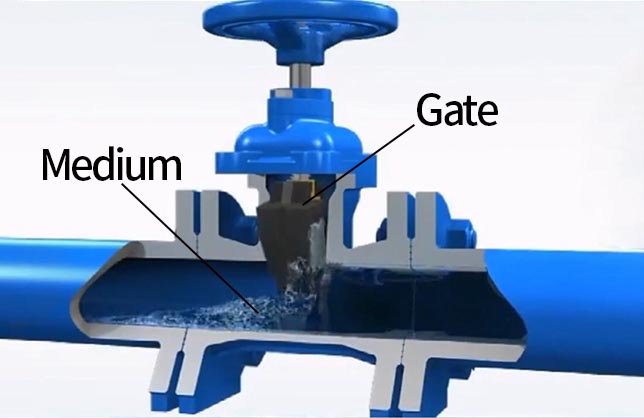

Principle of Gate Valve

The valve plate of the gate valve moves up and down vertically to the valve body. When the gate is fully raised, the inner cavity of the valve body is fully opened and the fluid can pass through unimpeded; when the gate is fully lowered, the fluid is completely blocked. The design of the gate valve makes it have almost no flow resistance when fully opened, so it is suitable for applications that require full opening or full closing. It should be emphasized here that the gate valve is suitable for full opening and full closing! However, the gate valve has a slow response speed, that is, the opening and closing time is longer, because it takes multiple turns to rotate the handwheel or worm gear to fully open and close.

2. Composition

Composition of butterfly valve

As mentioned above, the structure of the butterfly valve is relatively simple, including the main components such as the valve body, valve plate, valve shaft, valve seat and drive. As shown in the figure below.

Valve body:

The valve body of the butterfly valve is cylindrical and has a vertical channel inside. The valve body can be made of different materials, such as cast iron, ductile iron, stainless steel, carbon steel, aluminum bronze, etc. Of course, the choice of material depends on the use environment of the butterfly valve and the nature of the medium.

Valve plate:

The valve plate is the above-mentioned disc-shaped opening and closing part, which is similar to a disc in shape. The material of the valve plate is usually the same as that of the valve body, or higher than that of the valve body, because the butterfly valve is in direct contact with the medium, unlike the centerline butterfly valve where the valve body is directly separated from the medium by a valve seat. Some special media need to improve wear resistance, corrosion resistance, and high temperature resistance.

Valve stem:

The valve stem connects the valve plate and the drive, and is responsible for transmitting torque to rotate the valve plate. The valve stem is usually made of stainless steel 420 or other high-strength materials to ensure its sufficient strength and durability.

Valve seat:

The valve seat is lined in the inner cavity of the valve body and contacts the valve plate to form a seal to ensure that the medium does not leak when the valve is closed. There are two types of sealing: soft seal and hard seal. Soft seal has better sealing performance. Commonly used materials include rubber, PTFE, etc., which are commonly used in centerline butterfly valves. Hard seals are suitable for high temperature and high pressure environments. Commonly used materials include SS304+Flexible Graphite, etc., which are common in triple eccentric butterfly valves.

Actuator:

The actuator is used to drive the valve stem to rotate. Commonly used forms are manual, electric, pneumatic or hydraulic. Manual actuators are usually operated by handles or gears, while electric, pneumatic and hydraulic actuators can achieve remote control and automated operation.

Composition of gate valves

The gate valve structure is relatively complex. In addition to the valve body, valve plate, valve shaft, valve seat and drive, there are also packing, valve cover, etc. (see the figure below)

Valve body:

The valve body of the gate valve is usually barrel-shaped or wedge-shaped, with a straight-through channel inside. The valve body material is mostly cast iron, cast steel, stainless steel, brass, etc. Similarly, the appropriate material should be selected according to the use conditions.

Valve cover:

The valve cover is connected to the valve body to form a closed valve cavity. There is usually a stuffing box on the valve cover for installing packing and sealing the valve stem.

Gate + valve seat:

The gate is the opening and closing part of the gate valve, usually in a wedge shape. The gate can be a single gate or a double gate structure. The gate valve we commonly use is a single gate. The gate material of the elastic gate valve is GGG50 covered with rubber, and the gate of the hard seal gate valve is the body material + brass or stainless steel.

Valve stem:

The valve stem connects the gate and the actuator, and moves the gate up and down through threaded transmission. The valve stem material is generally high-strength materials such as stainless steel or carbon steel. According to the movement of the valve stem, gate valves can be divided into rising stem gate valves and non-rising stem gate valves. The valve stem thread of the rising stem gate valve is located outside the valve body, and the open and closed state is clearly visible; the valve stem thread of the non-rising stem gate valve is located inside the valve body, the structure is relatively compact, and the installation space is smaller than that of the rising stem gate valve.

Packing:

The packing is located in the stuffing box of the valve cover, which is used to seal the gap between the valve stem and the valve cover to prevent medium leakage. Common packing materials include graphite, PTFE, asbestos, etc. The packing is compressed by the gland to ensure sealing performance.

Actuator:

• The handwheel is the most common manual actuator, which drives the valve stem thread transmission by rotating the handwheel to move the gate up and down. For large-diameter or high-pressure gate valves, electric, pneumatic or hydraulic actuators are often used to reduce operating force and speed up opening and closing speed. Of course, this is another topic. If you are interested, please check out the article How Many Turns To Close A Butterfly Valve? How Long It Takes?

3. Cost

Cost of Butterfly Valve

Butterfly valves are usually cheaper than gate valves. This is because butterfly valves have a short structure length, require less materials, and have a relatively simple manufacturing process. In addition, butterfly valves are lighter, which also reduces the cost of transportation and installation. The cost advantage of butterfly valves is particularly obvious in large-diameter pipelines.

Cost of Gate Valve

The manufacturing cost of gate valves is usually higher, especially for large-diameter or high-pressure applications. The structure of gate valves is complex, and the machining accuracy of gate plates and valve seats is high, which requires more processes and time during the manufacturing process. In addition, gate valves are heavier, which increases the cost of transportation and installation.

As can be seen from the above drawing, for the same DN100, the gate valve is much larger than the butterfly valve.

4. Durability

Durability of Butterfly Valve

The durability of butterfly valves depends on its valve seat and valve body materials. In particular, the sealing materials of soft-sealed butterfly valves are usually made of rubber, PTFE or other flexible materials, which may wear or age during long-term use. Of course, the sealing materials of hard-sealed butterfly valves are made of high-performance synthetic materials or metal seals, so the durability has been significantly improved.

In general, butterfly valves have good durability in low-pressure and medium-pressure systems, but the sealing performance may be reduced in high-pressure and high-temperature environments.

It is also worth mentioning that butterfly valves can isolate the medium by wrapping the valve body with the valve seat to prevent the valve body from being corroded. At the same time, the valve plate can be fully encapsulated with rubber and fully lined with fluorine, which significantly improves its durability for corrosive media.

Durability of gate valves

The elastic seat seal design of gate valves faces the same problem as butterfly valves, that is, wear and aging during use. However, hard-sealed gate valves perform well in high-pressure and high-temperature environments. Because the metal-to-metal sealing surface of the gate valve has high wear resistance and corrosion resistance, its service life is usually longer.

However, the gate of the gate valve is easily stuck by impurities in the medium, which may also affect its durability.

In addition, its appearance and structure determine that it is difficult to make a full lining, so for the same corrosive medium, whether it is made of all metal or full lining, its price is much higher than that of the gate valve.

5. Flow regulation

Flow regulation of butterfly valve

The three-eccentric butterfly valve can adjust the flow at different openings, but its flow characteristic curve is relatively nonlinear, especially when the valve is close to fully open, the flow changes greatly. Therefore, the butterfly valve is only suitable for scenes with low adjustment accuracy requirements, otherwise, a ball valve can be selected.

Flow regulation of gate valve

The gate valve is designed to be more suitable for full opening or full closing operations, but not for regulating flow. In the partially open state, the gate will cause turbulence and vibration of the fluid, which is easy to damage the valve seat and gate.

6. Installation

Installation of butterfly valve

The installation of butterfly valve is relatively simple. It is light in weight, so it does not require too much support during installation; it has a compact structure, so it is particularly suitable for occasions with limited space.

The butterfly valve can be installed on pipes in any direction (horizontal or vertical), and there is no strict requirement for the flow direction in the pipe. It should be noted that in high-pressure or large-diameter applications, the butterfly plate must be in the fully open position during installation to avoid damage to the seal.

Installation of gate valves

The installation of gate valves is more complicated, especially large-diameter and hard-sealed gate valves. Due to the large weight of gate valves, additional support and fixing measures are required during installation to ensure the stability of the valve and the safety of the installer.

Gate valves are usually installed on horizontal pipes, and the flow direction of the fluid needs to be considered to ensure correct installation. In addition, the opening and closing stroke of gate valves is long, especially for rising-stem gate valves, and sufficient space needs to be reserved to operate the handwheel.

7. Maintenance and maintenance

Maintenance of butterfly valves

Butterfly valves have fewer parts and are easy to disassemble and assemble, so they are easier to maintain. In daily maintenance, the aging and wear of the valve plate and valve seat are mainly checked. If the sealing ring is found to be severely worn, it needs to be replaced in time. Therefore, we recommend that customers purchase replaceable soft-back butterfly valves. If the surface flatness and finish of the valve plate are difficult to achieve a good sealing effect, it also needs to be replaced.

In addition, there is the lubrication of the valve stem. Good lubrication helps the flexibility and durability of the butterfly valve operation.

Maintenance of gate valves

Gate valves have many parts and are difficult to disassemble and assemble, especially in large pipeline systems, where the maintenance workload is large. During maintenance, special attention should be paid to whether the gate is lifted and lowered smoothly and whether there are foreign objects in the groove of the valve body.

If the contact surface of the valve seat and the gate is scratched or worn, it needs to be polished or replaced. Of course, the lubrication of the valve stem is also necessary.

More attention should be paid to the maintenance of the packing than the butterfly valve. The packing of the gate valve is used to seal the gap between the valve stem and the valve body to prevent the medium from leaking out. Aging and wear of the packing are common problems of gate valves. During maintenance, it is necessary to regularly check the tightness of the packing and adjust or replace it if necessary.

8. Conclusion

In summary, butterfly valves and gate valves have their own advantages and disadvantages in terms of performance, cost, durability, flow regulation and installation:

1. Principle: Butterfly valves have fast opening and closing speeds and are suitable for fast opening and closing occasions; gate valves have long opening and closing times.

2. Composition: Butterfly valves have a simple structure and gate valves have a complex composition.

3. Cost: Butterfly valves have a lower cost, especially for large-diameter applications; gate valves have a higher cost, especially for high pressure or special material requirements.

4. Durability: Butterfly valves have better durability in low-pressure and medium-pressure systems; gate valves perform well in high-pressure and high-temperature environments, but frequent opening and closing may affect their lifespan.

5. Flow regulation: Butterfly valves are suitable for rough flow control; gate valves are more suitable for full open or full closed operations.

6. Installation: Butterfly valves are easy to install and are applicable to both horizontal and vertical pipelines; gate valves are complex to install and are suitable for horizontal pipeline installation.

7. Maintenance: The maintenance of butterfly valves focuses on the wear and aging of the valve plate and valve seat, and the lubrication of the valve stem. In addition to these, the gate valve also needs to maintain the packing.

In practical applications, the selection of butterfly valves or gate valves needs to be comprehensively considered according to specific working conditions and requirements to ensure the best performance and economy.