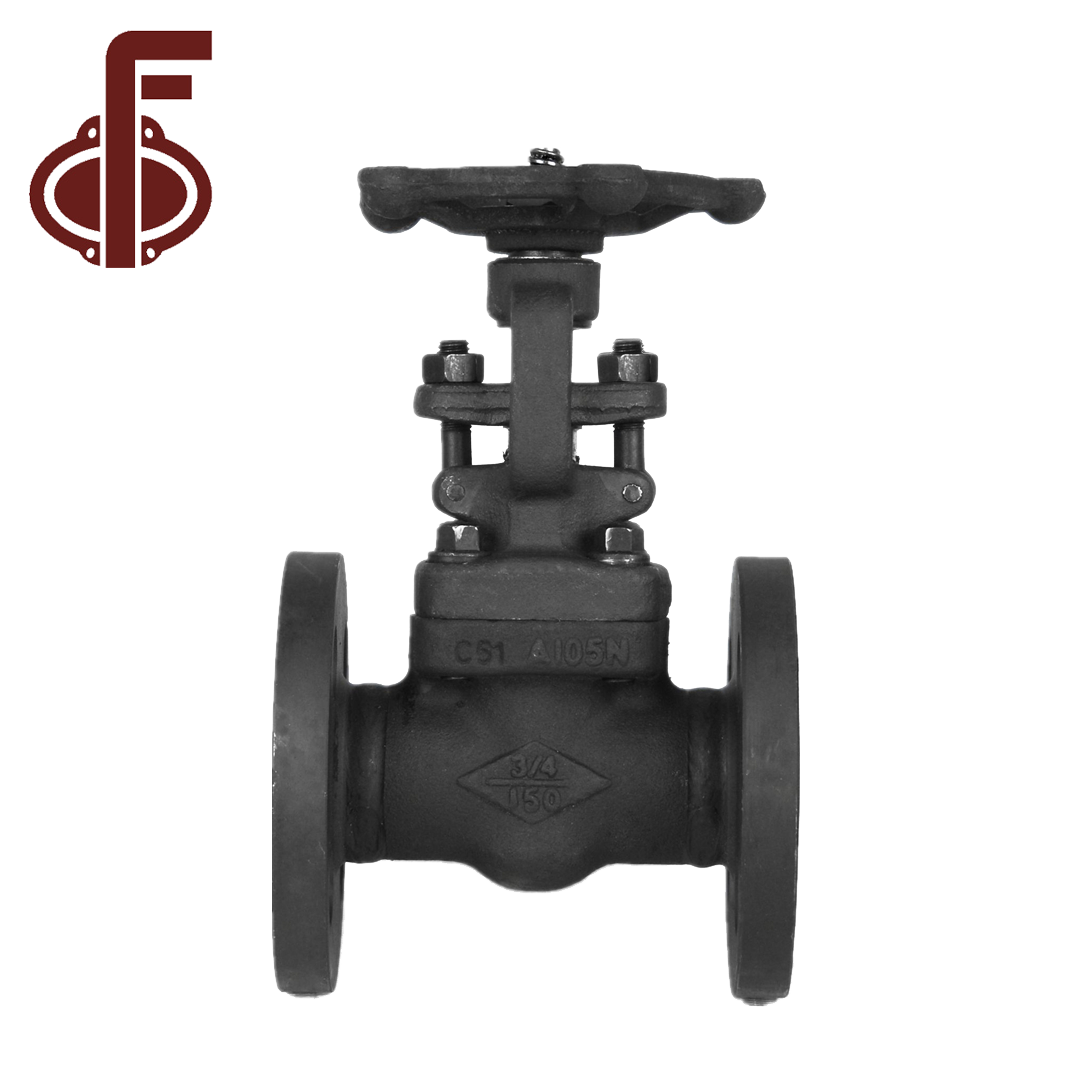

Class1200 Forged Gate Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN15-DN50 |

| Pressure Rating | CL800-1200 |

| Face to Face STD | BS5163, DIN3202 F4, API609 |

| Connection STD | BS 4504 PN6/PN10/PN16, DIN2501 PN6/PN10/PN16, ISO 7005 PN6/PN10/PN16, JIS 5K/10K/16K, ASME B16.1 125LB, ASME B16.1 150LB, AS 2129 Table D and E |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Forged Steel /F316 |

| Disc | WCB/CF8M |

| Stem/Shaft | 2Cr13stainless steel/CF8M |

| Seat | WCB+2Cr13stainless steel/CF8M |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Gear Box, Electric Actuator, Pneumatic Actuator |

| Temperature | Temperature: -20-425℃ |

Product Display

Product Advantage

A forged steel gate valve is a type of valve typically used in high-pressure and high-temperature applications. It is designed to regulate the flow of fluid in a pipeline by opening and closing a gate (a wedge or disk). The forged steel construction provides strength and durability, making it suitable for demanding industrial environments. These valves are commonly used in industries such as oil and gas, petrochemical, and power generation.

1. High strength and toughness: The valve body material of the forged steel gate valve is high-quality low carbon steel and alloy steel, which is produced through the forging process and has high strength and toughness.

2. Good wear resistance: The valve body has high hardness and good wear resistance, and can resist the wear of sand, slurry and other media.

3. Small fluid resistance: The sealing surface of the forged steel gate valve is smooth, the fluid resistance is small, and no sedimentation or blockage will occur.

4. Easy maintenance: the closing parts (gate plates) slide and friction makes maintenance more convenient.

5. Wide scope of application: Forged steel gate valves can be used in various types of pipelines with wide flow capacity.