1. Introduction to Butterfly Valves

1.1. Definition and Basic Functions

A butterfly valve is a device that regulates the flow in a pipe. It is controlled by rotating the disc a quarter turn. They are usually used in applications where they close quickly.

1.2. History of Butterfly Valves

Butterfly valves can be traced back to the late 19th century. The prototype of the modern butterfly valve was born in the mid-20th century. After decades of development, it has become a versatile solution for controlling media in various industries.

The technological development of butterfly valves has not stopped. In the future, butterfly valves will be lighter and more compact. They can also be applied to extreme conditions (such as ultra-high pressure and ultra-low temperature). Perhaps they can be used in new applications in the field of renewable energy, such as solar energy, wind energy and green hydrogen energy projects.

1.3. Application of Butterfly Valves in Various Industries

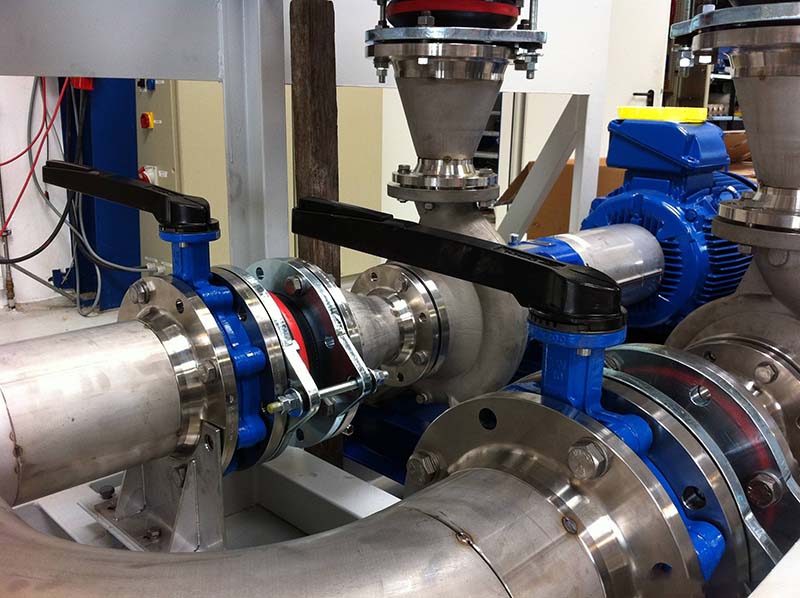

1.3.1. Water Treatment and Distribution

In water treatment plants and distribution systems. Butterfly valves are indispensable. They effectively regulate and isolate the flow of drinking water. Their low pressure drop and bidirectional sealing capabilities are particularly beneficial in ensuring a continuous water supply.

1.3.2. HVAC Systems

In heating and air conditioning (HVAC) systems, butterfly valves are used to control water circulation. Their ease of automation makes them suitable for regulating both cold and hot water systems.

1.3.3. Chemical and Petrochemical Plants

Triple offset and high-performance butterfly valves can handle a wide range of chemicals, including corrosive and abrasive fluids. Their ability to operate at extreme temperatures and pressures makes them suitable for applications such as chemical processing, storage, and delivery systems.

1.3.4. Oil and Gas Industry

The oil and gas industry relies on butterfly valves for applications such as pipeline isolation, flow regulation, and tank systems. The compatibility of butterfly valves with a wide range of materials ensures their safe operation in the oil and gas industry.

1.3.5. Food and Beverage Processing

Hygiene is a top priority in food and beverage processing. Butterfly valves with sanitary designs and polished surfaces can be used to maintain cleanliness and prevent contamination when handling liquids such as juices, dairy products, and beverages. Both wras-certified rubber and food-grade stainless steel can meet this standard.

1.3.6. Marine and Shipbuilding

Aluminum bronze butterfly valves are designed for marine applications to control ballast systems, cooling water, and fuel lines. The corrosion-resistant materials of butterfly valves make them ideal for use in harsh marine environments.

1.3.7. Power Plants

In power plants, butterfly valves are used in cooling systems, steam lines, and flue gas desulfurization systems. They are capable of handling high pressure and high temperature fluids.

1.3.8. Wastewater Treatment Plants

Butterfly valves are essential for managing sludge, aeration, and water flows in wastewater treatment facilities.

1.3.9. Pulp and Paper Industry

The pulp and paper industry benefits from butterfly valves in processes such as pulp cooking, bleaching, and chemical recovery. Their resistance to abrasive pulp and chemicals increases operational efficiency and service life.

2. Construction of Butterfly Valve

2.1. Components of Butterfly Valve

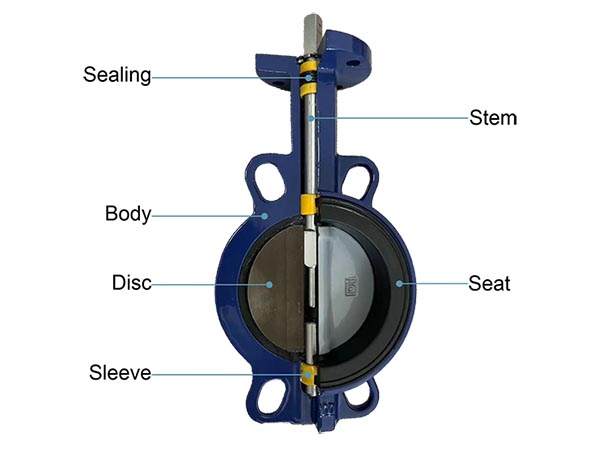

Key components include:

Valve body: The house that houses the other internal components.

Valve disc: Opens and closes by rotating 90 degrees.

Stem: Connects the disc to the actuator.

Seat: Provides a seal to prevent leakage.

2.2. Types of butterfly valves based on structure

Wafer type: Installed between flanges of the pipe and fixed with bolts.

Lug type: Uses threaded inserts for installation.

Flange type: Has two flanges and is installed with the pipe.

2.3. Materials of butterfly valves

Body: Cast iron, stainless steel or carbon steel.

Disc: Ductile iron (nickel-plated, nylon, PTFE, and EPDM, etc.), WCB, stainless steel, bronze.

Seat: Rubber, Teflon or metal.

3. Working principle of butterfly valve

3.1. Operation of butterfly valve

The butterfly valve works by rotating the disc mounted on the central stem. The position of the disc determines the flow regulation.

3.2. Types of driving methods of butterfly valves

Manual: Operated by handle and worm gear.

Pneumatic: Uses compressed air.

Electric: Controlled by electric motor.

Hydraulic: Driven by fluid pressure (less commonly used).

3.3. Advantages and limitations of butterfly valves

Advantages: compact design (short structure length), low cost (less material), quick operation (90-degree rotation).

Limitations: Butterfly valves cannot be used to cut off high-hardness particles, viscous fluids and fibrous impurities.

3.4. Types of butterfly valves

3.4.1 Resilient seat butterfly valve

Features: The valve seat is generally made of elastic materials such as rubber and PTFE, and the seal is tight.

Use case: low pressure and low temperature applications.

3.4.2. High-performance butterfly valve (double offset butterfly valve)

Features: Double offset design, durable.

Use case: low and medium pressure systems.

3.4.3. Triple offset butterfly valve

Features: Metal seat seal without friction.

Use case: extreme temperature and pressure.

4. Installation and maintenance of butterfly valves

4.1 Correct installation method of butterfly valves

Open the butterfly valve plate at an angle of 0-90 degrees.

Make sure to keep enough clearance from other components.

Make sure the valve plate does not touch the pipe flange.

Verify alignment and clearance of disc rotation.

4.2. Daily maintenance of butterfly valves

Check for wear and replace if necessary.

Lubricate moving parts as needed.

4.3. Common troubleshooting problems and solutions

Leaks: Check seat integrity.

Stuck: Clean seat area debris and ensure proper lubrication.

5. Comparison with other valve types

5.1 Butterfly valve vs. ball valve

Butterfly valve: Lighter and more compact.

Ball valve: More suitable for full bore flow, can be used as viscous and fibrous fluids.

5.2. Butterfly valve vs. gate valve

Butterfly valve: Fast operation.

Gate valve: More suitable for full opening and closing.