DN100 PN16 Wafer Butterfly Valve WCB Body

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | WCB(A216) |

| Disc | Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

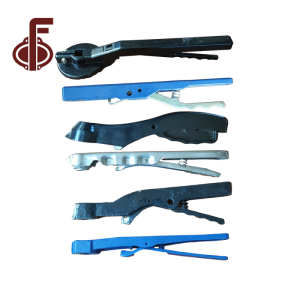

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Ductile iron: suitable for media such as water, steam, air and oil with PN≤4.0MPa and temperature of -30~350℃. Commonly used grades include: QT400-15, QT450-10, QT500-7.

Carbon steel (WCA, WCB, WCC): suitable for nominal pressure PN ≤ 32.0MPa, suitable for medium and high-pressure valves with working temperatures between -29~+425℃, of which the working temperatures of 16Mn and 30Mn are -29~595 ℃, often used to replace ASTM A105. Commonly used grades include WC1, WCB, and high-quality steel 20, 25, 30 and low-alloy structural steel 16Mn.

FAQ

About Company:

Q: Are you a Factory or Trading?

A: We’re a factory with 17 years production experience, OEM for some customers around the world.

Q: What is your After-sales service term?

A: 18 months for all our products.

Q: Do you accept custom design on size?

A: Yes.

Q: What's your terms of payment?

A : T/T, L/C.

Q: What is your transportation method?

A: By sea, by air mainly, we also accept express delivery.

About Products:

1. What is a single flange butterfly valve body?

A single flange butterfly valve body is a main component of the single flanged butterfly valve, is a type of valve used to control the flow of a fluid in a piping system. It consists of a disc that rotates around a central axis which allows for quick and efficient flow control.

2. What are the applications of a single flange butterfly valve?

Single flange butterfly valves are commonly used in various industries such as water treatment, sewage treatment, chemical processing, and power generation. They are also used in HVAC systems and in shipbuilding.

3. What are the advantages of a single flange butterfly valve?

Some of the advantages of a single flange butterfly valve include its lightweight and compact design, low pressure drop, ease of installation, and low maintenance requirements. As its FTF is the same with wafer butterfly valve.

4. What is the temperature range for a single flange butterfly valve?

The temperature range for a single flange butterfly valve depends on the material of construction. Generally, they can handle temperatures ranging from -20°C to 120°C, but higher temperature materials are available for more extreme applications.

5. Can a single flange butterfly valve be used for both liquid and gas applications?

Yes, single flange butterfly valves can be used for both liquid and gas applications, making them versatile for a wide range of industrial processes.

6. Are single flange butterfly valves suitable for use in potable water systems?

Yes, single flange butterfly valves can be used in potable water systems as long as they are made from materials that comply with the relevant drinking water regulations and standards, so we get the WRAS certificates.