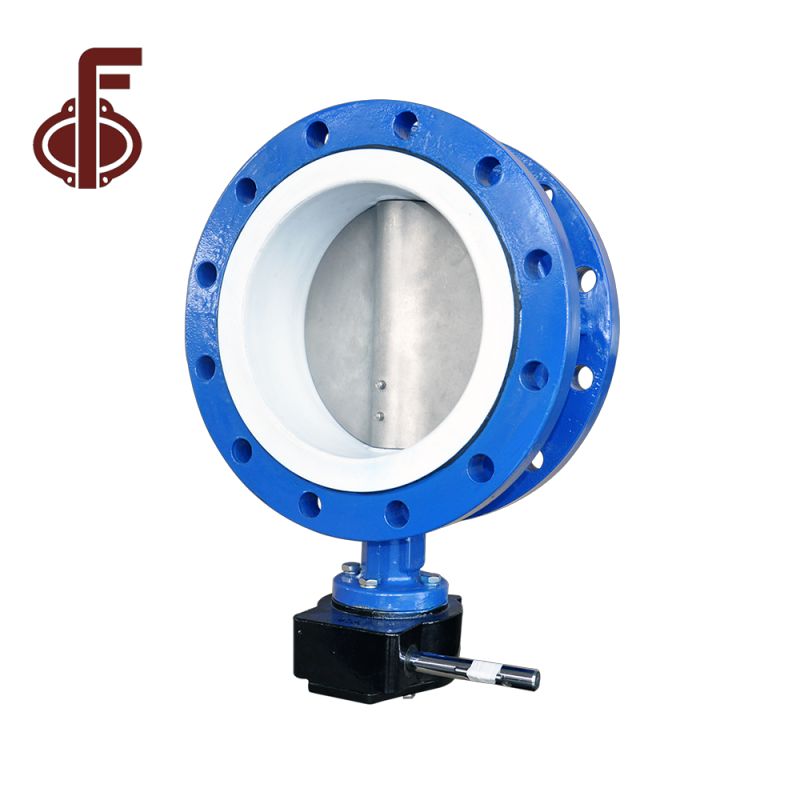

Factory Cheap Butterfly Valve For Water Line - PTFE Seat Flange Type Butterfly Valve – Zhongfa

Factory Cheap Butterfly Valve For Water Line - PTFE Seat Flange Type Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

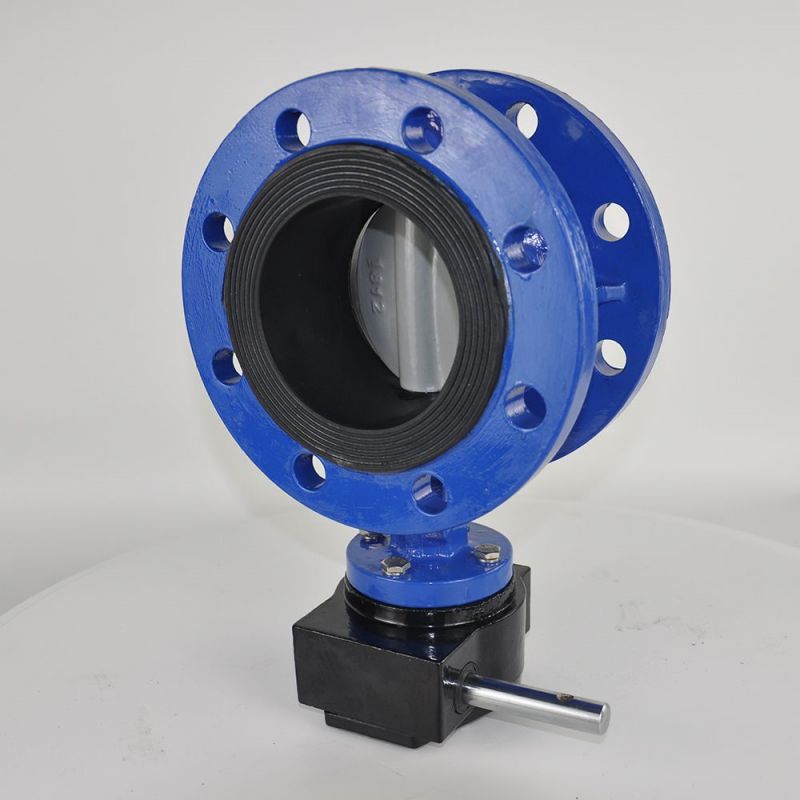

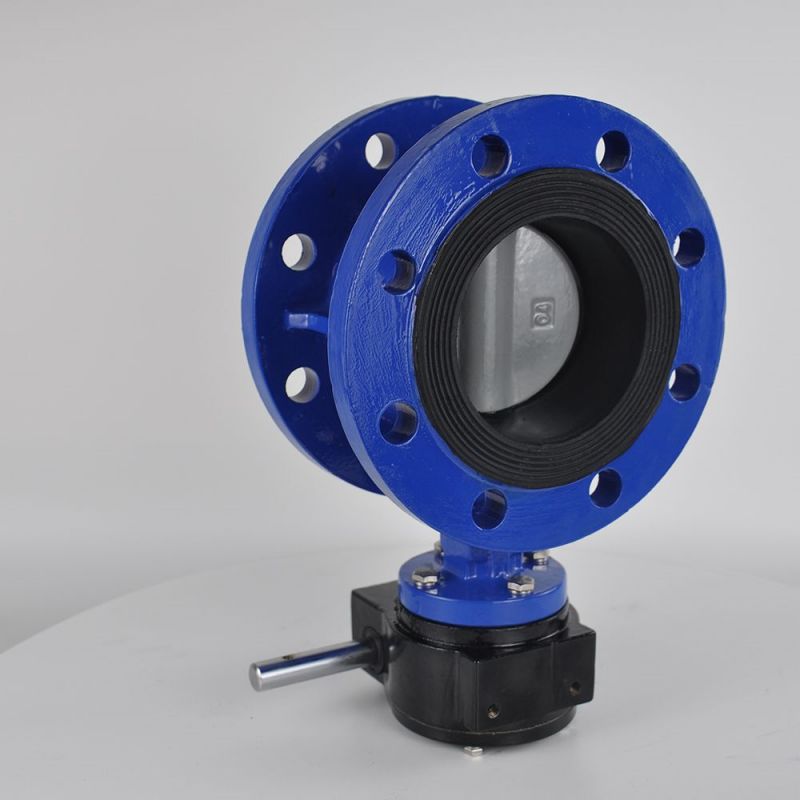

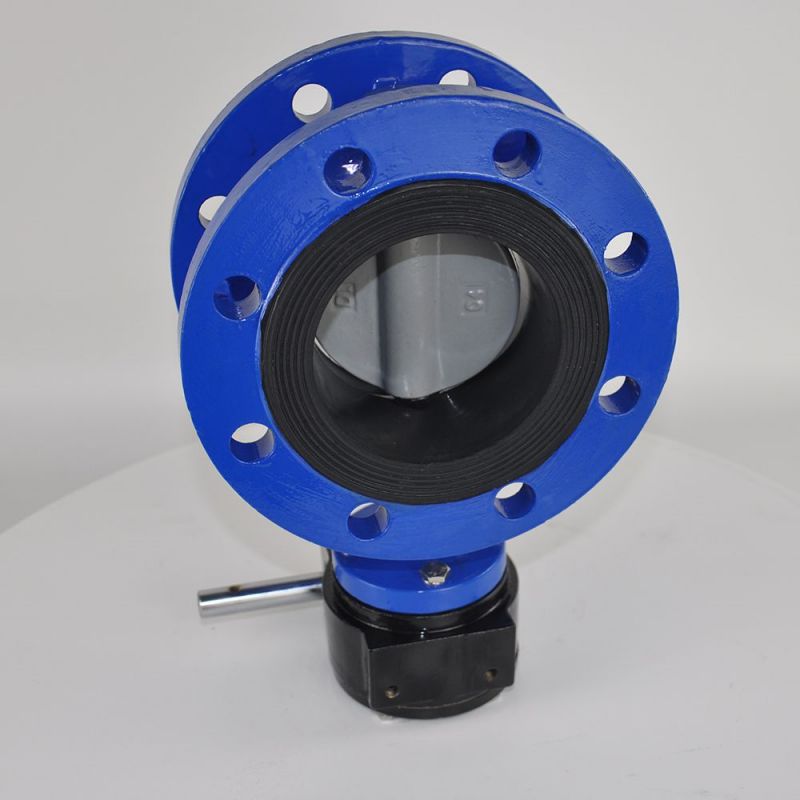

Product Display

Product Advantage

Our valve connection standards include DIN, ASME, JIS, GOST, BS etc., it’s easy for customers to choose the suitable valve, help our customers reduce their stock.

Our valve has standard thickness according to GB26640, makes it capable of holding high pressure when needed.

Our valve seat use imported nature rubber, with more than 50% of rubber inside. The seat has a good elasticity property, with long service life. It can be open and close more than 10,000 times with no damage for the seat.

The valve seat is wide edge seat, sealing gap is wider than regular type, makes the sealing for connection easier. Wider seat also easy to install than narrow seat. The stem direction of the seat has lug boss, with O ring on it, archive the second sealing of the valve.

Each valve should be cleaned by ultra-sonic cleaning machine, in case of contaminant left inside, guarantee the cleaning of the valve, in case of pollution to the pipeline.

The valve body use high adhesive force epoxy resin powder, helps it adhere to the body after melting.

Bolts and nuts use ss304 material, with higher rust protection capability.

Handle of the valve use ductile iron, is anti-corrosion than regular handle. Spring and pin use ss304 material. Handle part use semicircle structure, with good touch feeling.

Non-pin stem design adopts anti-blowout structure, the valve stem adopt double jump ring, not only can compensate the error in installation, but also can stop the stem being blow off.

Each product of ZFA has material report for the main parts of the valve.

Company Advantage

Valve Parts Machining: We not only supply valve, but also valve parts, mainly body, disc, stem and handle. Some of our regular customers keeping order valve parts more than 10 years, we also produce valve parts mold according to your drawing.

OEM: We’re OEM manufacturer for famous customers in Moscow(Russia), Barcelona(Spain), Texas(USA), Alberta(Canada) and 5 other countries.

Machines: We have total 30 machines (include CNC, machine center, semi-auto machine, pressure testing machine, spectrograph etc.) mainly used for valve part machining.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Factory Cheap Butterfly Valve For Water Line - PTFE Seat Flange Type Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Mauritius, Adelaide, St. Petersburg, Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.