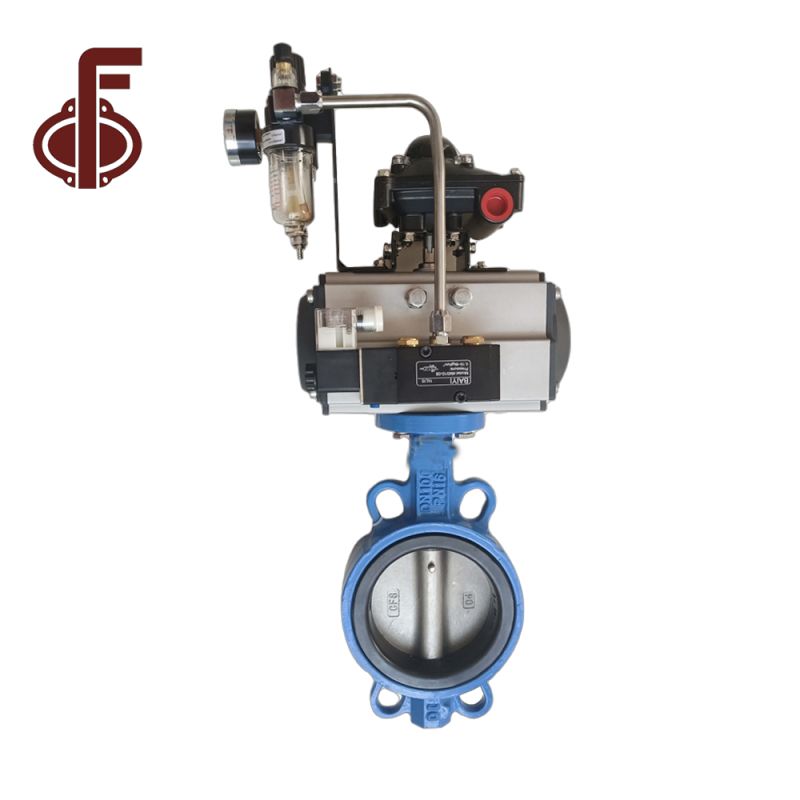

Factory Wholesale Double Offset Butterfly Valve - Pneumatic Actuator Wafer Butterfly Valves – Zhongfa

Factory Wholesale Double Offset Butterfly Valve - Pneumatic Actuator Wafer Butterfly Valves – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

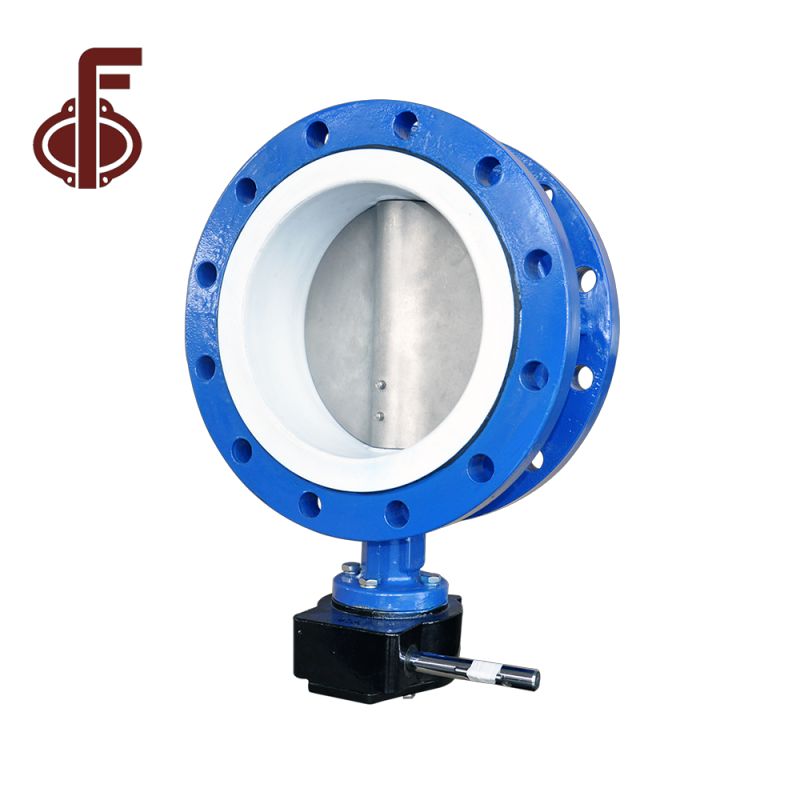

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Our valve has standard thickness according to GB26640, makes it capable of holding high pressure when needed.

Our valve seat use imported nature rubber, with more than 50% of rubber inside. The seat has a good elasticity property, with long service life. It can be open and close more than 10,000 times with no damage for the seat.

The valve seat with 3 bushing and 3 O ring, helps supporting the stem and guarantee the sealing.

The valve body use high adhesive force epoxy resin powder, helps it adhere to the body after melting.

Bolts and nuts use ss304 material, with higher rust protection capability.

Butterfly valve pin use modulation type, high strength, wear-resisting and safe connection.

Each product of ZFA has material report for the main parts of the valve.

The valve adopt epoxy powder painting process, thickness of tht powder is 250um at least. Valve body should be heating 3 hours under 200℃, powder should be solidify for 2 hours under 180℃.

Pneumatic actuator adopt double piston structure, with high precision and effective, and stable output torque.

Special Test: According to customer’s requirement, we can do any test you need.

ZFA Valve strictly execute API598 standard, we do both side pressure testing for all the valve 100%, guarantee deliver 100% quality valves to our customers.

All valve body casted by precise casting body, DI, WCB, Stainless Steel and many other materials, with perfect appearance, each batch has its casting stove number, easy to trace for material protection.

We use CNC machining to process the valve disc, control the precision of the valve by ourselves, guarantee good sealing property from low to high temperature.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Factory Wholesale Double Offset Butterfly Valve - Pneumatic Actuator Wafer Butterfly Valves – Zhongfa , The product will supply to all over the world, such as: Azerbaijan, Philadelphia, Uganda, During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

We have been looking for a professional and responsible supplier, and now we find it.