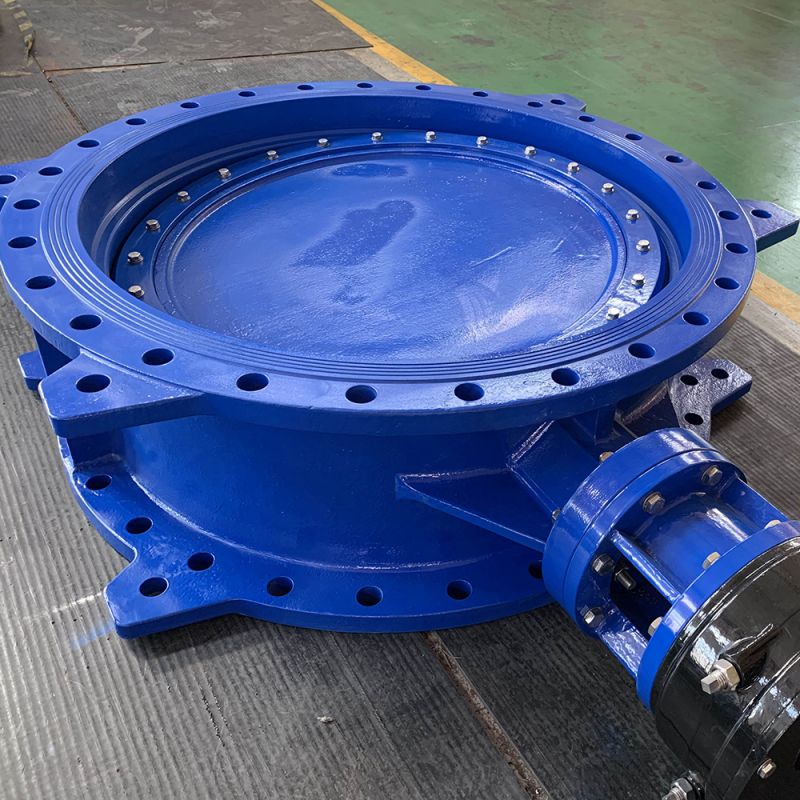

Good Wholesale Vendors Lever Operated Butterfly Valve - Ductile Iron Flange Type Eccentric Butterfly Valve – Zhongfa

Good Wholesale Vendors Lever Operated Butterfly Valve - Ductile Iron Flange Type Eccentric Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1600 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

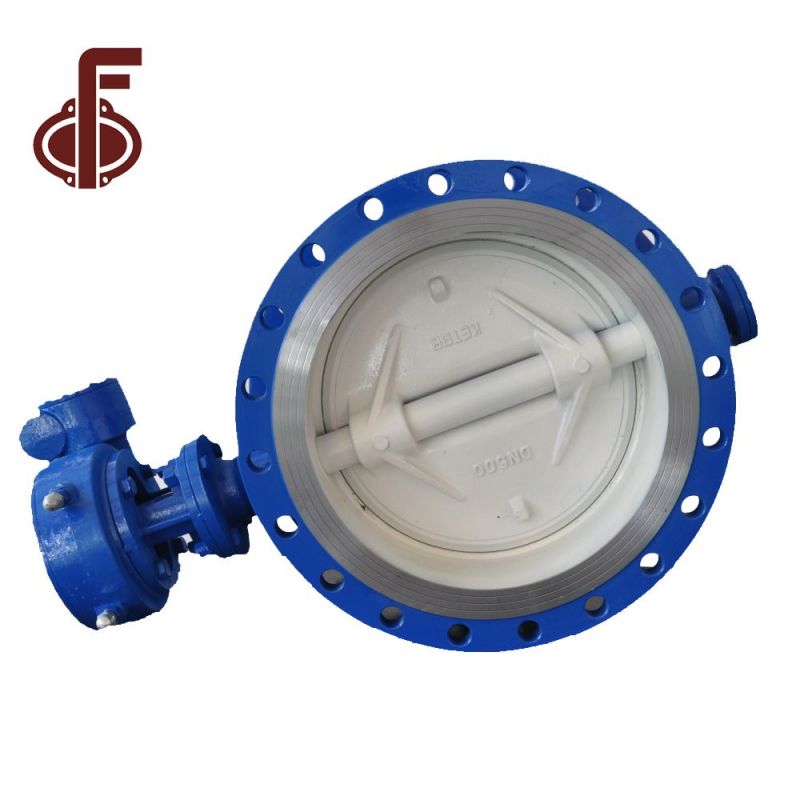

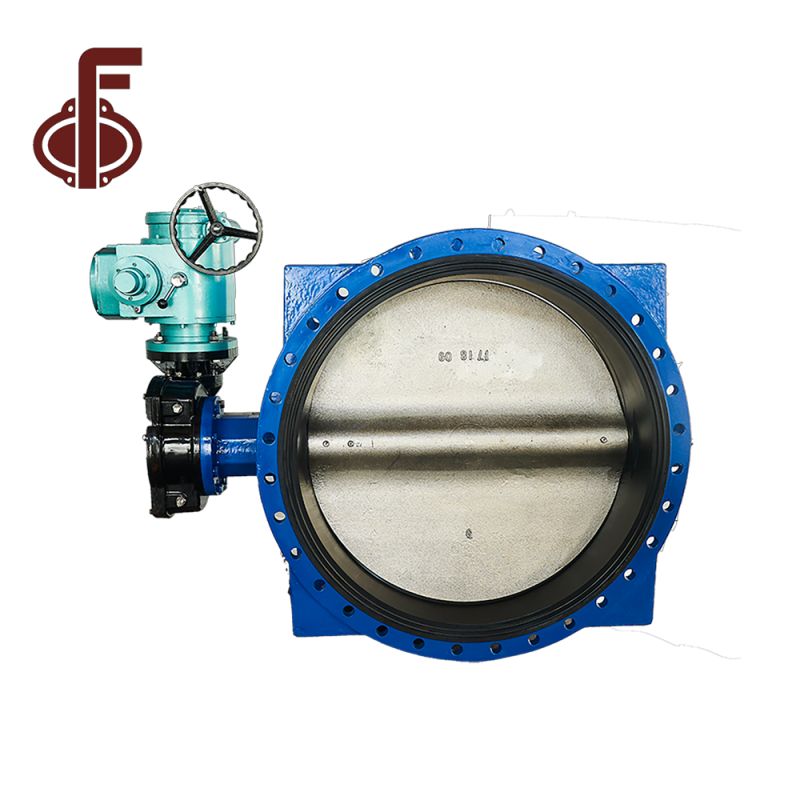

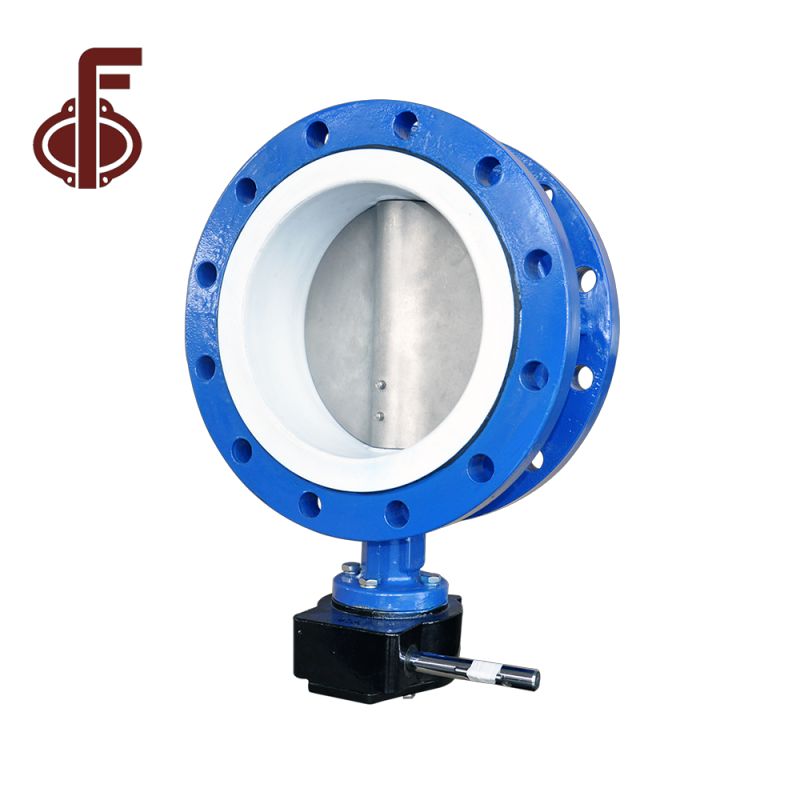

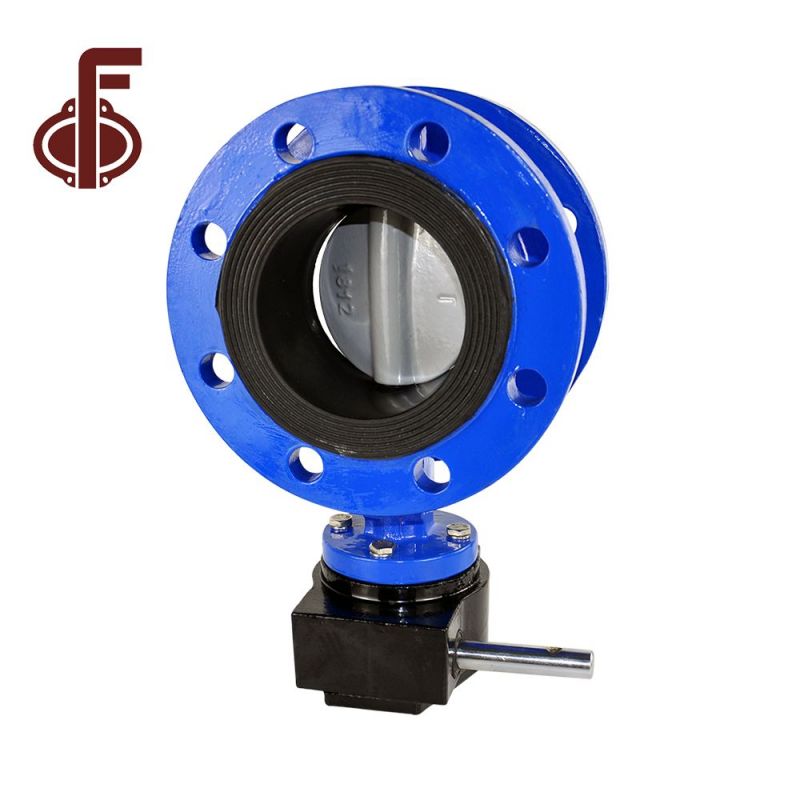

Product Display

Product Description

Reasonable design, compact structure, convenient disassembly and assembly, and convenient maintenance.

The eccentric structure is adopted to reduce the friction of the sealing ring and prolong the service life.

Simple and compact structure, light weight, 90° rotation, fast and flexible opening and closing.

The valve body is equipped with a foundation support, which can be installed vertically or horizontally.

Easy to install and disassemble for easy maintenance.

Soft-seal eccentric structure telescopic flanged butterfly valve is a new type of structure that integrates flanged butterfly valve and expansion joint, and is deeply trusted by users for its good performance. This product is mainly used for water supply and drainage of water plants, power plants, steel plants, petrochemicals, pharmaceuticals, food, textiles, papermaking and other systems, as the renovation and maintenance of old pipelines and replacement of matching valves, especially when water is used as a regulator and the use of water as a regulating valve.

ZFA polymer and elastomer seats provide bi-directional, drop-proof closure under vacuum and full differential pressure rating. Its unique design does not rely on pressure to assist sealing, so it seals under high and low pressures and in dirty environments. Multiple materials for optimum seat life in all applications.

For added safety, an anti-blowout shaft is standard on all valves.

Unique packaging design allows use under pressure and vacuum without modification or special assembly.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good Wholesale Vendors Lever Operated Butterfly Valve - Ductile Iron Flange Type Eccentric Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Palestine, Qatar, Armenia, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.