High Quality For Wafer Check Valve - Ductile Iron SS304 SS316 Non-return Swing Check Valve – Zhongfa

High Quality For Wafer Check Valve - Ductile Iron SS304 SS316 Non-return Swing Check Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN50-DN600 |

| Pressure Rating | PN6,PN10, PN16, CL150-600 |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, DIN 2501 PN6/10/16, BS5155 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

Product Display

Product Advantage

Check valve, also known as one-way valve, check valve, back pressure valve, this type of valve is automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, and belongs to an automatic valve. The function of the check valve is to prevent the backflow of the medium, the reverse rotation of the pump and its driving motor, and the discharge of the medium in the container. Double-plate check valve is a very common type of check valve. By choosing different materials, the wafer check valve can be applied to water, steam, oil in petrochemical, metallurgy, electric power, light industry, food and other industries. , nitric acid, acetic acid, strong oxidizing medium and urea and other media.

The swing check valve adopts a built-in rocker arm swing structure. All the opening and closing parts of the valve are installed inside the valve body and do not penetrate the valve body. Except for the sealing gasket and sealing ring used in the middle flange, the overall There is no leakage point, eliminating the possibility of valve leakage. The connection between the rocker arm and the disc of the swing check valve adopts a spherical connection structure, so that the disc has a certain degree of freedom in the range of 360 degrees, and has proper trace position compensation. It is mainly used in petroleum, chemical, pharmaceutical, fertilizer, etc. , electricity and other pipelines. Suitable for clean media, not suitable for media containing solid particles and high viscosity

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

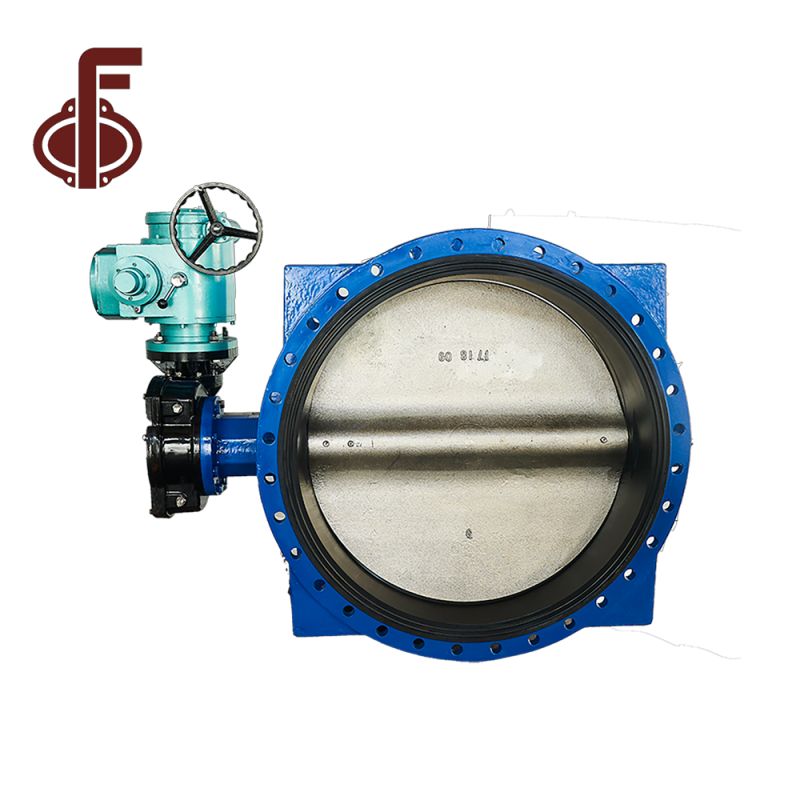

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for High Quality For Wafer Check Valve - Ductile Iron SS304 SS316 Non-return Swing Check Valve – Zhongfa , The product will supply to all over the world, such as: Anguilla, New Orleans, Nepal, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.