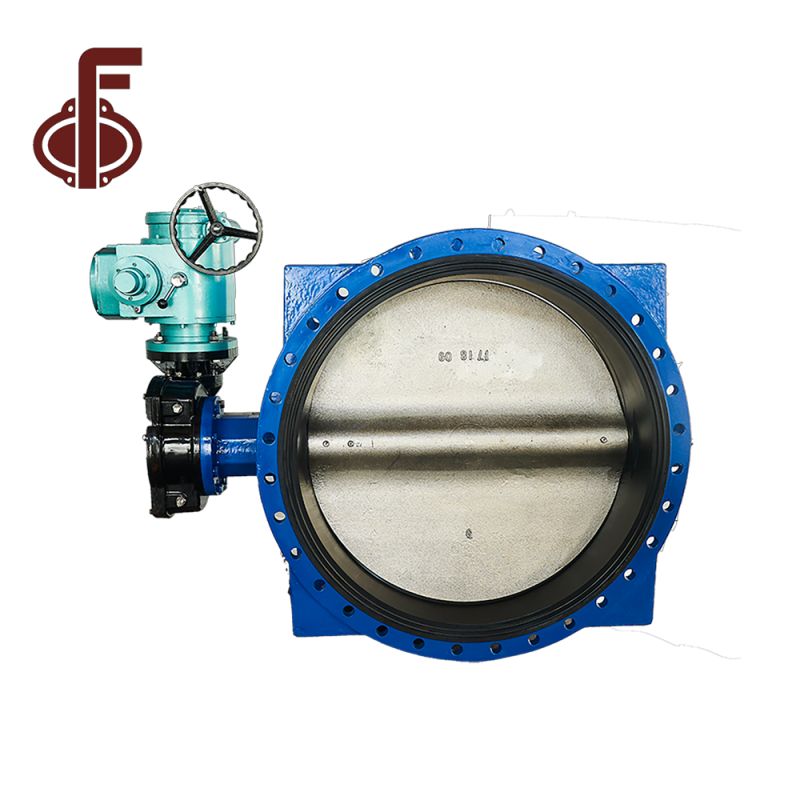

Hot Sale For Pneumatic Operated Butterfly Valve - Electric Flange Butterfly Valves – Zhongfa

Hot Sale For Pneumatic Operated Butterfly Valve - Electric Flange Butterfly Valves – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

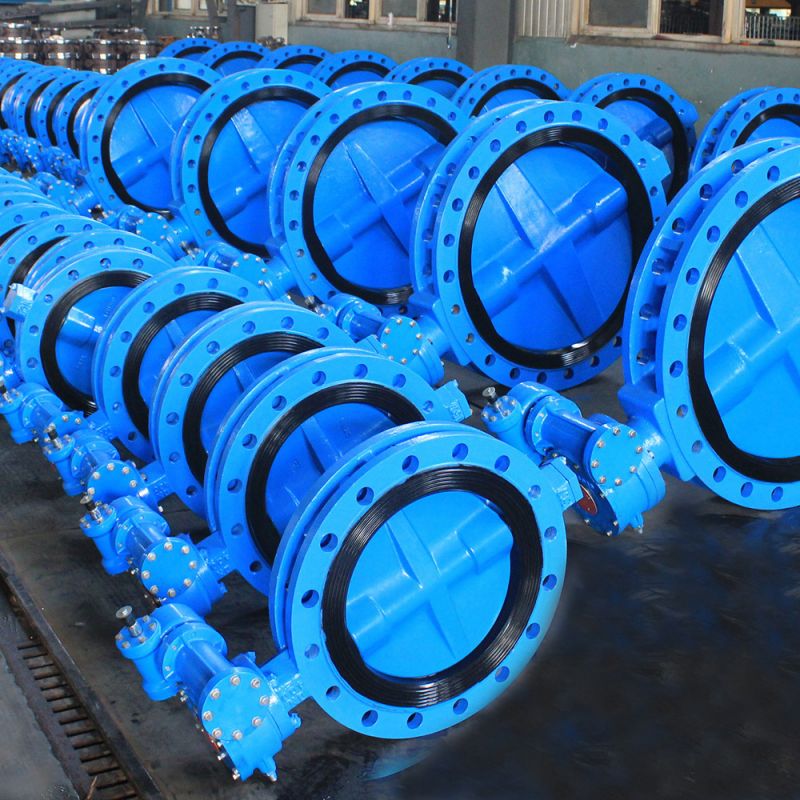

Product Display

Product Advantage

Marker Plate located on body side of the valve, easy to watch after installation. Material of the plate is SS304, with laser marking. We use stainless steel rivet to fix it, makes it clean and tightening.

Bolts and nuts use ss304 material, with higher rust protection capability.

Handle of the valve use ductile iron, is anti-corrosion than regular handle. Spring and pin use ss304 material. Handle part use semicircle structure, with good touch feeling.

Butterfly valve pin use modulation type, high strength, wear-resisting and safe connection.

Non-pin stem design adopts anti-blowout structure, the valve stem adopt double jump ring, not only can compensate the error in installation, but also can stop the stem being blow off.

Each product of ZFA has material report for the main parts of the valve.

ZFA Valve body use solid valve body, so the weight is higher than regular type.

The valve adopts epoxy powder painting process, thickness of the powder is 250um at least. Valve body should be heating 3 hours under 200℃, powder should be solidified for 2 hours under 180℃.

After natural cooling, the adhesive of the powder is higher than regular type, guarantee there’s no color change in 36 months.

Pneumatic actuators adopt double piston structure, with high precision and effective, and stable output torque.

Body Test: The valve body test use 1.5 times pressure than standard pressure. The test should be done after installation, the valve disc is half close, called body pressure test. The valve seat uses 1.1 times pressure than standard pressure.

Special Test: According to customer’s requirement, we can do any test you need.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Hot Sale For Pneumatic Operated Butterfly Valve - Electric Flange Butterfly Valves – Zhongfa , The product will supply to all over the world, such as: Mauritius, Rio de Janeiro, Kuwait, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.