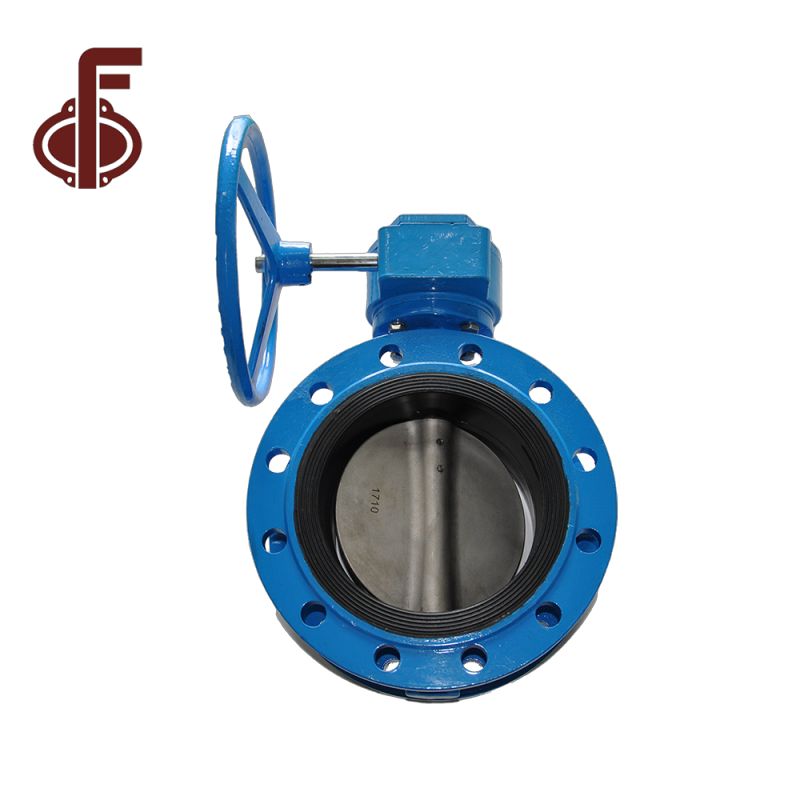

Hot-Selling Electric Butterfly Valve - Triple Offset Butterfly Valve – Zhongfa

Hot-Selling Electric Butterfly Valve - Triple Offset Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1600 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

The disc cone pin is positioned tangentially, half in the disc and half in the shaft, making it in compression rather than shear, which eliminates the possibility of failure.

The rocker-shaped gland bridge compensates for uneven adjustment of the gland nut and reduces packing leakage.

Integral cast disc position stops perfectly position the disc in the seat for maximum seat and seal life.

Double eccentric configuration, reliable sealing performance, ensures that the valve disc will not contact the sealing seat when starting, solves the problem of uneven load on the sealing seat, prolongs the service life, and has the advantages of high temperature resistance, wear resistance, corrosion resistance, etc., ensuring reliable sealing performance.

Small size, light weight, easy installation and maintenance.

Double eccentric butterfly valve is also called high performance butterfly valve. It is mainly used for the drainage of water plants, power plants, iron and steel plants, chemicals, water source projects, environmental facilities construction, etc. It is especially suitable for water supply pipelines as adjustment and cutting equipment.

Compared with the centerline butterfly valve, the double eccentric butterfly valve is more resistant to high pressure, has a longer life and better stability. Compared with other valves, the larger the diameter, the lighter the material and the lower the cost. But because there is a butterfly plate in the middle, the flow resistance is large, so the butterfly valve smaller than DN200 is of little significance.

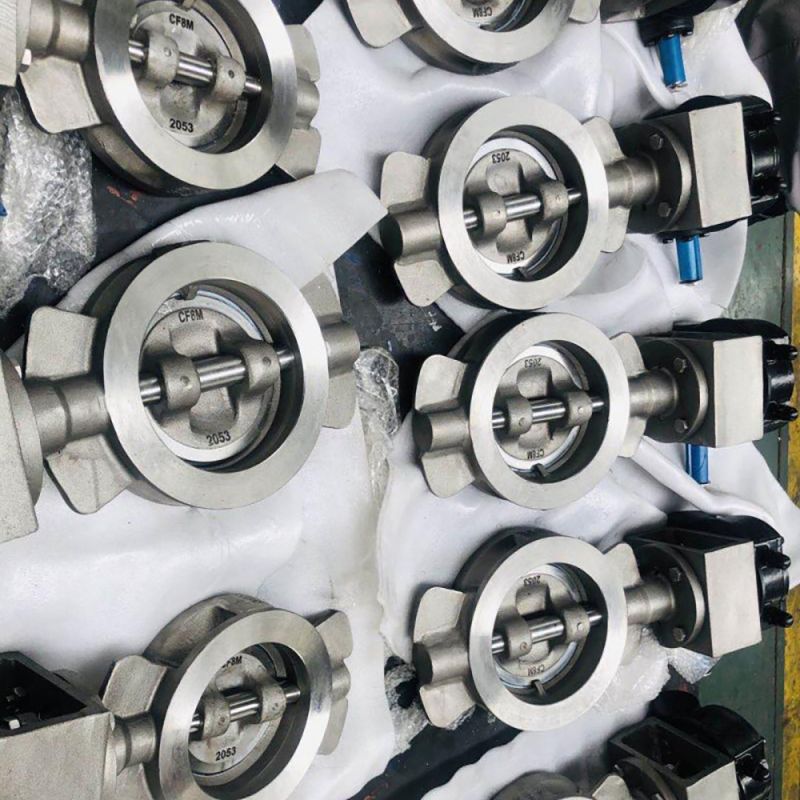

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Hot-Selling Electric Butterfly Valve - Triple Offset Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Pakistan, Bolivia, Egypt, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.