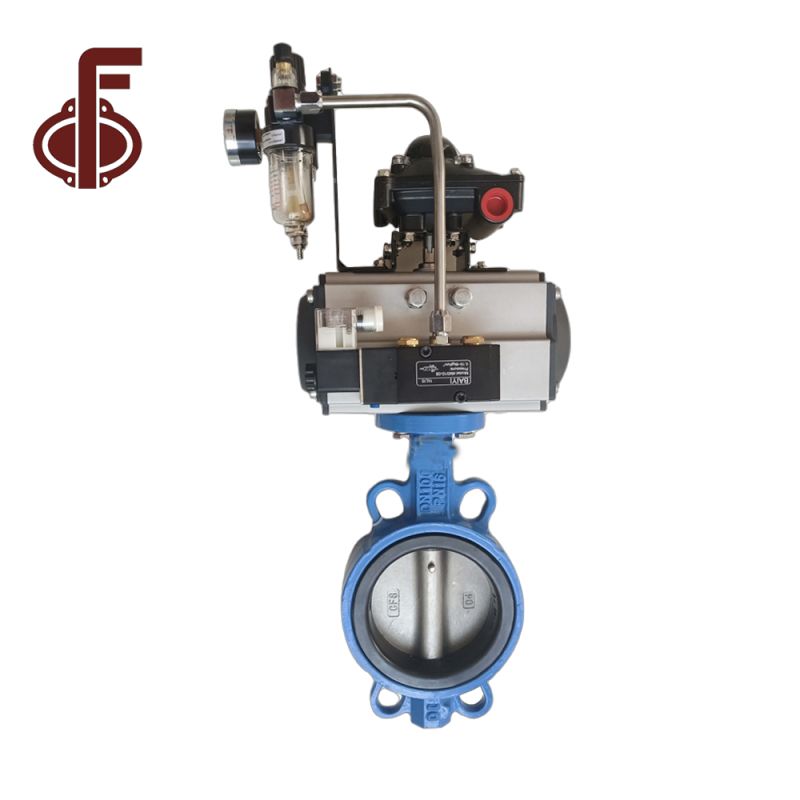

Manufacturer Of Air Butterfly Valve - U Section Flange Butterfly Valve – Zhongfa

Manufacturer Of Air Butterfly Valve - U Section Flange Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Simple structure, good interchangeability and low price.

The valve stem seal is not easy to deform, avoids normal valve stem leakage, and the overall support is good, stable and firm.

The less seat rubber, the less likely it is to swell, making it easier to keep torque within the proper range.

The two-piece valve stem with pinless connection has a simple and compact structure, and is very convenient for maintenance and disassembly.

The butterfly plate has the function of automatic centering, and the butterfly plate and the valve seat are closely matched

The phenolic back seat is non-shedding, stretch-resistant, leak-proof and easy to replace.

The gear operated U-shaped butterfly valve is mounted between two flanges. Butterfly valves are held in place by bolts or studs and nuts between the flanges. Of course, it is not possible to disconnect only one side of the piping system from the valve with this type of installation.

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

All surfaces of the valve interior is clean, dry and free from grease before painting. The valve surfaces coated with epoxy coating approved for drinking water applications.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Manufacturer Of Air Butterfly Valve - U Section Flange Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Philippines, Belgium, Auckland, We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.