Products

-

WCB Wafer Type Butterfly Valve

WCB wafer type butterfly valve refers to a butterfly valve constructed from WCB (cast carbon steel) material and designed in a wafer type configuration. The wafer type butterfly valve is commonly used in applications where space is limited because of its compact design. This type of valve is often used in HVAC, water treatment, and other industrial applications.

-

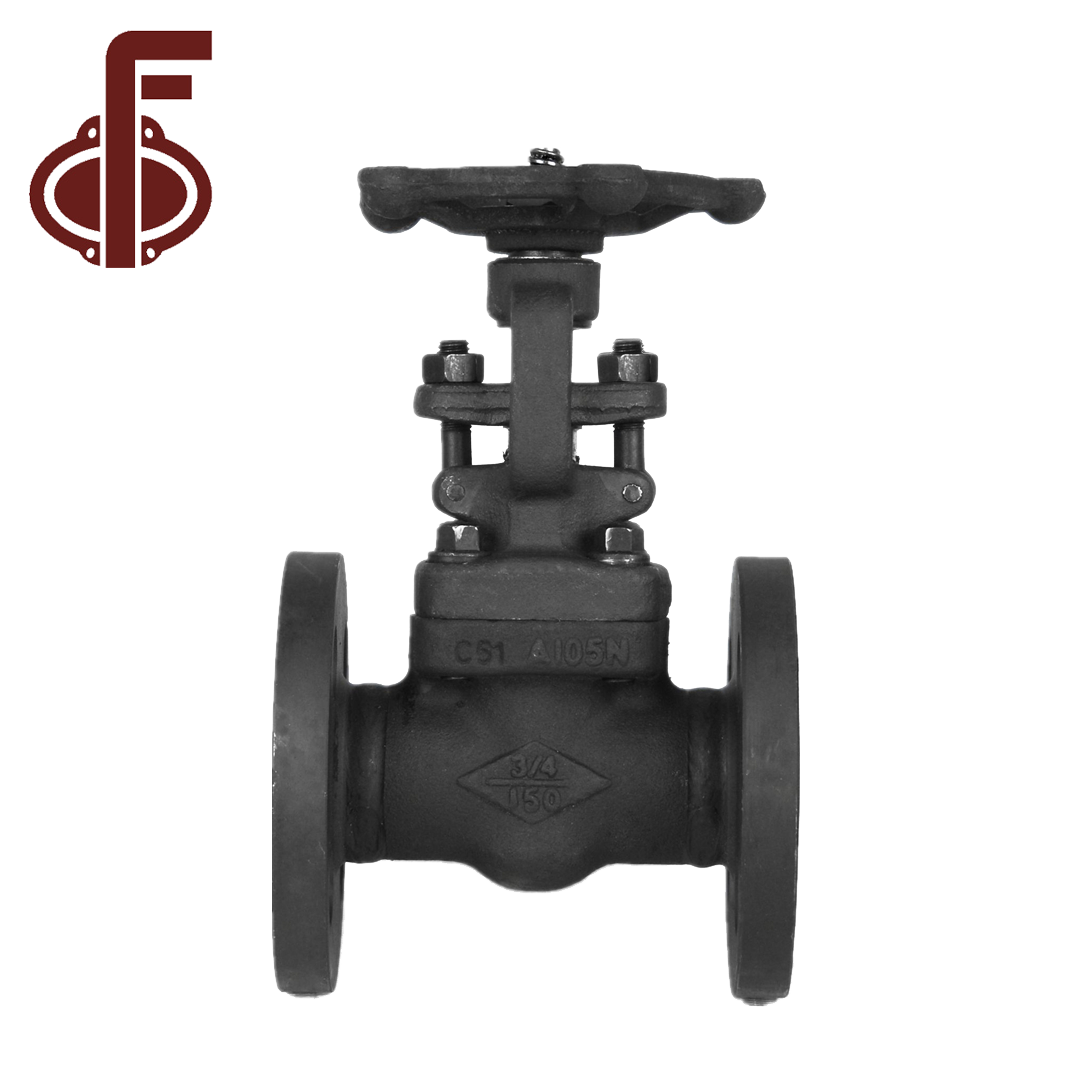

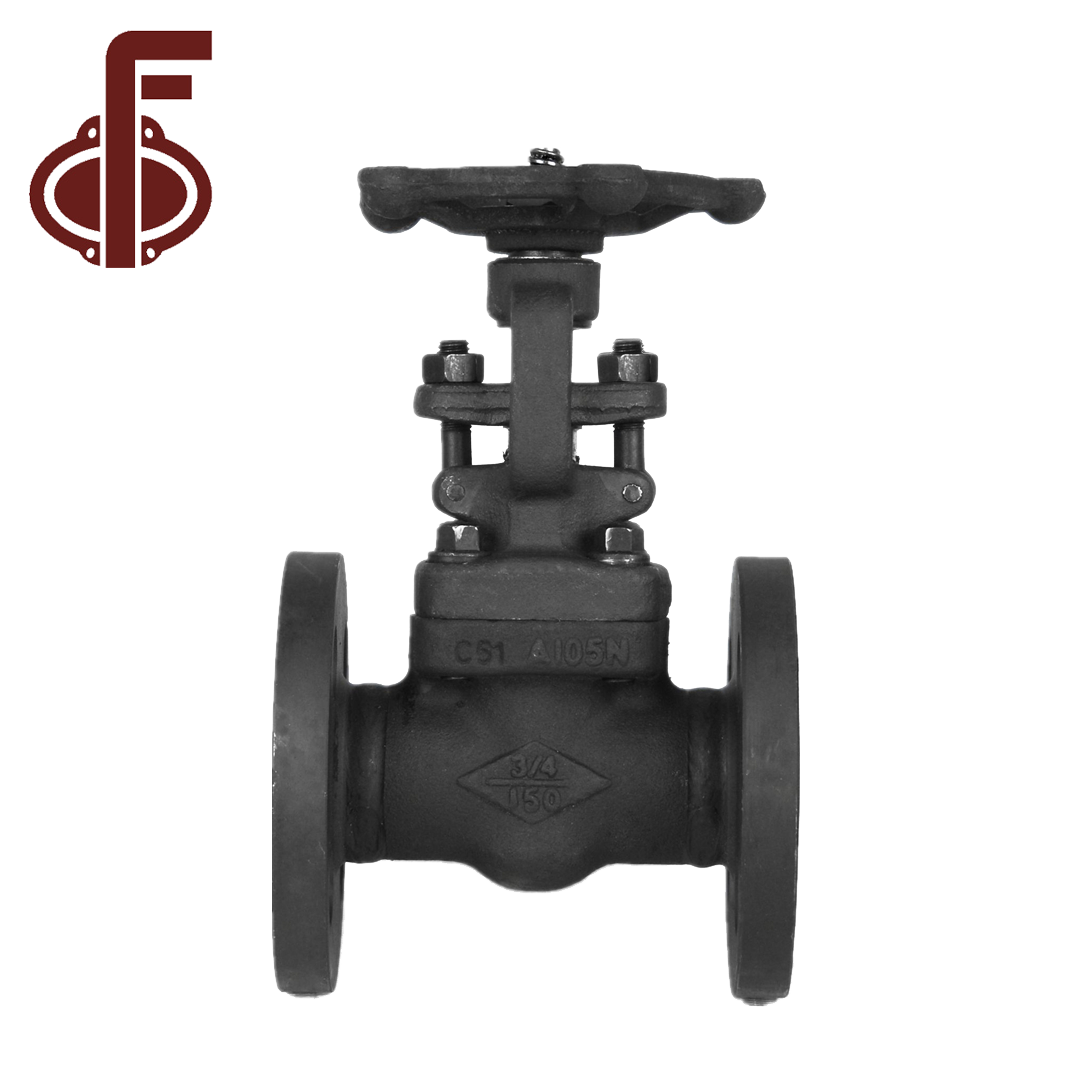

Class1200 Forged Gate Valve

Forged steel gate valve is the suitable for the small diameter pipe, we can do DN15-DN50,High temperature resistance, corrosion resistance, good sealing and solid structure, suitable for piping systems with high pressure, high temperature and corrosive media

-

Earless Wafer Type Butterfly Valve

The most outstanding feature of the earless butterfly valve is that there is no need to consider the connection standard of the ear, so it can be applied to a variety of standards

-

Soft/Hard Back Seat Butterfly Valve Seat

The soft/hard back seat in a butterfly valve is a component that provides a sealing surface between the disc and the valve body.

A soft seat is typically made of materials such as rubber, PTFE, and it provides a tight seal against the disc when closed. It is suitable for applications where bubble-tight shut-off is required, such as in water or gas pipelines.

-

Ductile Iron Single Flanged Wafer Type Butterfly Valve Body

Ductile iron single Flanged butterfly valve, the connection is multi-standard, be connected to PN10, PN16, Class150, Jis5K/10K, and other standards of pipeline flange, making this product widely used in the world. it is are suitable for some common projects such as water treatment, sewage treatment, hot and cold air conditioning, etc.

-

SS2205 Dual Plate Check Valve

Dual plate check valve also called wafer type butterfly check valve. This kind of check vavle has good non-return performance, safety and reliability, small flow resistance coefficient. It is mainly used in petroleum,chemical, food, water supply and drainage, and energy systems. A wide range of materials are available, such as cast iron, ductile iron, stainless steel and so on.

-

Stainless Steel Body WCB Single Disc Check Valve PN16

A Stainless Steel Body WCB Single Disc Check Valve PN16 is a non-return valve designed to prevent backflow in pipelines, ensuring unidirectional flow for media like water, oil, gas, or other non-aggressive fluids. -

30s41nj GOST 12820-80 20Л/20ГЛ PN16 PN40 Gate Valve

GOST standard WCB/LCC gate valve is usually hard seal gate valve, the material can be used WCB, CF8, CF8M, high temperature, high pressure and corrosion resistance, This steel gate valve is for Russia market, Flange connection standard according to GOST 33259 2015, Flange standars according to GOST 12820.

-

PN10/16 150LB DN50-600 Basket Strainer

Basket type pipeline filter is the pipeline transport liquid process to remove solid impurities equipment. When the liquid flows through the filter, the impurities are filtered out, which can protect the normal work of pumps, compressors, instruments and other equipment. When it is necessary to clean, just take out the detachable filter cartridge, remove the filtered out impurities and then re-install it. The material can be cast iron, carbon steel and stainless steel.