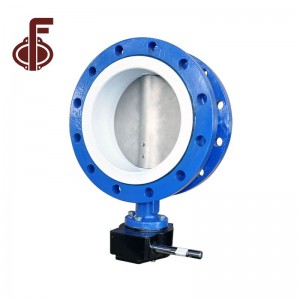

PTFE Lined Disc & Seat Wafer Butterfly Valve

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN600 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216) coated with PTFE |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | PTFE/RPTFE |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Difference between PTFE Seat of PTFE iner:

The PTFE valve seat is wrapped on the hard rubber backing and directly formed into the overall structure of the valve seat.

Installed in the valve body to provide sealing performance.

PTFE lining is a layer of PTFE that is applied to the inside of the valve body, including the end faces where it connects to the pipe.

PTFE-lined Disc and PTFE seat butterfly valves are widely used in chemical, pharmaceutical, power generation and other industries. These valves are specifically designed to control the flow of corrosive fluids.

The PTFE lining inside the valve offers excellent corrosion and high temperature resistance, making it ideal for a variety of industrial applications. The wafer style design of these butterfly valves makes them lightweight and easy to install between flanges.

PTFE seat wafer butterfly valves are known for their durability and low maintenance requirements. The valve's disc design reduces turbulence and enables high flow rates, making it a cost-effective solution for industrial applications. The compact design of these valves facilitates installation in industrial environments and saves valuable space.