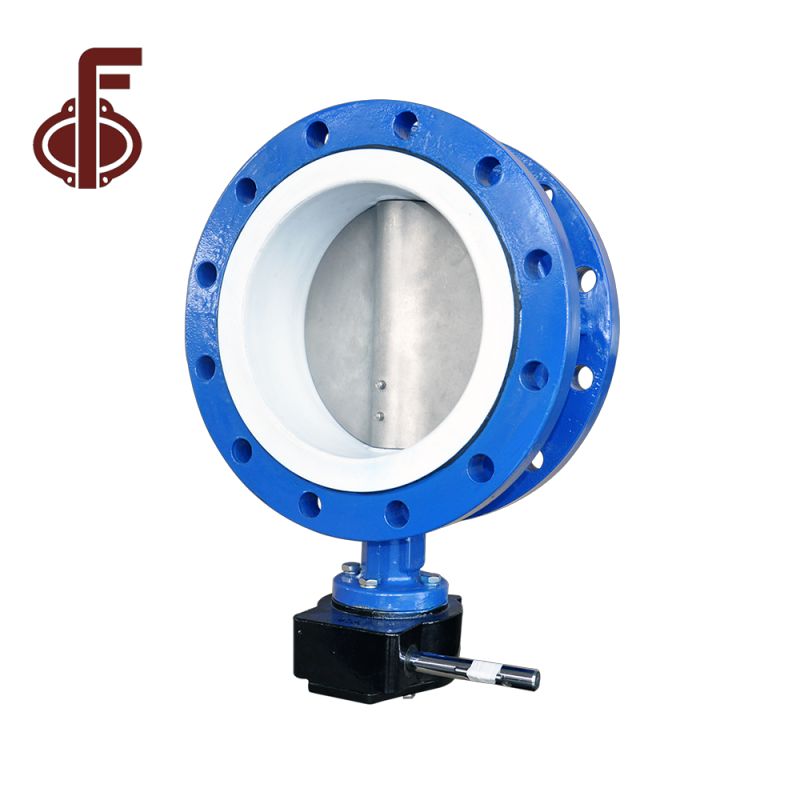

Rapid Delivery For 24 Inch Butterfly Valve - Worm Gear Wafer Butterfly Valve – Zhongfa

Rapid Delivery For 24 Inch Butterfly Valve - Worm Gear Wafer Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

We use CNC machining to process the valve disc, control the precision of the valve by ourselves, guarantee good sealing property from low to high temperature.

Our valve stem is stainless steel material, the strength of the valve stem is better after tempering, reduce the transformation possibility of valve stem.

The quality inspection from the blank to the finished product is 100% guaranteed.

Suitable Media: Wafer and other neutral medium, working temperature from -20 to 120℃, the application of the valve can be municipal construction, wafer conservancy project, water treatment etc.

ZFA Valve strictly execute API598 standard, we do both side pressure testing for all the valve 100%, guarantee deliver 100% quality valves to our customers.

ZFA Valve focus on valves production for 17 years, with professional production team, we can help our customers to archive your goals with our stable quality.

ZFA Valve body use solid valve body, so the weight is higher than regular type.

The valve adopt epoxy powder painting process, thickness of tht powder is 250um at least. Valve body should be heating 3 hours under 200℃, powder should be solidify for 2 hours under 180℃.

After natural cooling, the adhesive of the powder is higher than regular type, guarantee there’s no color change in 36 months.

Marker Plate located on body side of the valve, easy to watch after installation. Material of the plate is SS304, with laser marking. We use stainless steel rivet to fix it, makes it cleaning and tighting.

Bolts and nuts use ss304 material, with higher rust protection capability.

Handle of the valve use ductile iron, is anti-corrosion than regular handle. Spring and pin use ss304 material. Handle part use semicircle structure, with good touch feeling.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Rapid Delivery For 24 Inch Butterfly Valve - Worm Gear Wafer Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Armenia, kazakhstan, Japan, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.