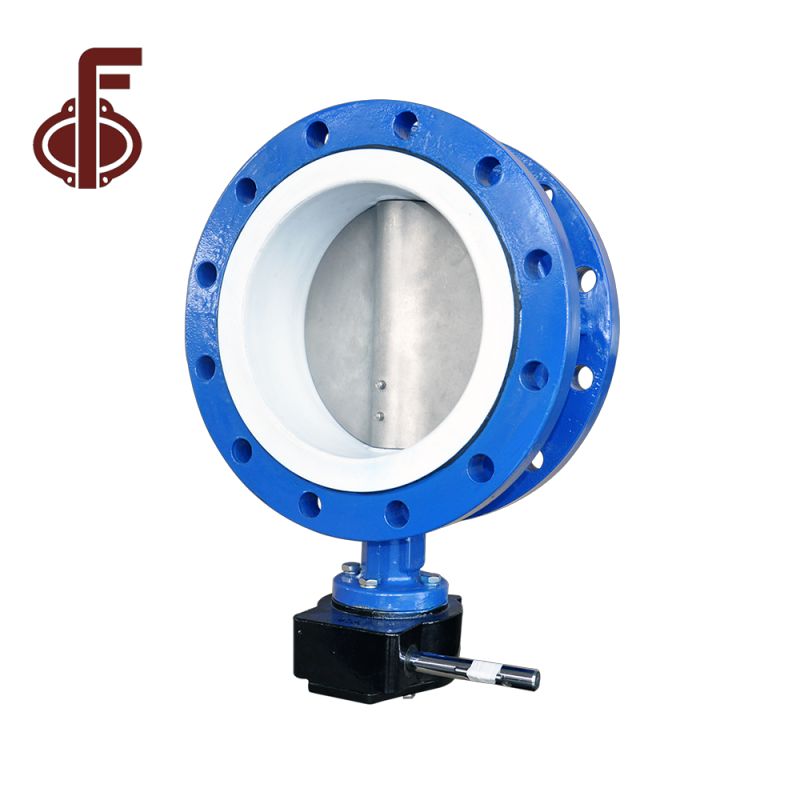

Super Purchasing For Ss 304 Butterfly Valve - NBR Seat Flange Butterfly Valve – Zhongfa

Super Purchasing For Ss 304 Butterfly Valve - NBR Seat Flange Butterfly Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN4000 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

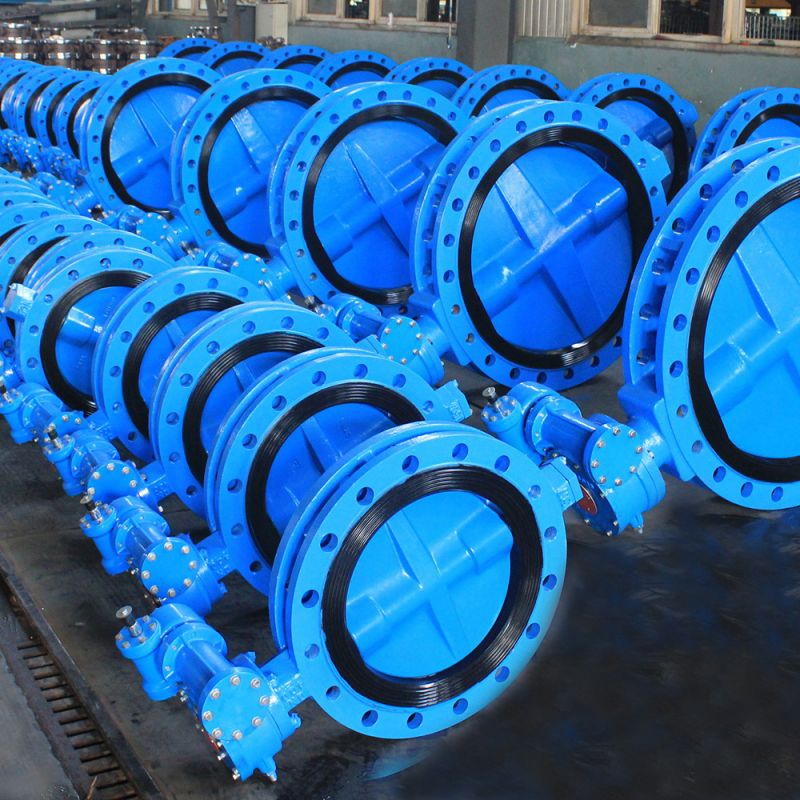

Product Display

Product Advantage

Our valve has standard thickness according to GB26640, makes it capable of holding high pressure when needed.

The valve body use GGG50 material, has higher mechanical property, rate of spheroidization more than 4 class, makes the ductility of the material more than 10 percent. Compared to regular cast iron, it can suffer higher pressure.

The valve seat with 3 bushing and 3 O ring, helps supporting the stem and guarantee the sealing.

Each valve should be cleaned by ultra-sonic cleaning machine, in case of contaminant left inside, guarantee the cleaning of the valve, in case of pollution to the pipeline.

Bolts and nuts use ss304 material, with higher rust protection capability.

Handle of the valve use ductile iron, is anti-corrosion than regular handle. Spring and pin use ss304 material. Handle part use semicircle structure, with good touch feeling.

Non-pin stem design adopts anti-blowout structure, the valve stem adopt double jump ring, not only can compensate the error in installation, but also can stop the stem being blow off.

Each product of ZFA has material report for the main parts of the valve.

ZFA Valve body use solid valve body, so the weight is higher than regular type.

Pneumatic actuators adopt double piston structure, with high precision and effective, and stable output torque.

Body Test: The valve body test use 1.5 times pressure than standard pressure. The test should be done after installation, the valve disc is half close, called body pressure test. The valve seat uses 1.1 times pressure than standard pressure.

Special Test: According to customer’s requirement, we can do any test you need.

Company Advantage

Our valves are compliance with valve international standard of ASTM, ANSI, ISO, BS, DIN, GOST, JIS, KS and so on. Size DN40-DN1200, nominal pressure: 0.1Mpa~2.0Mpa, suitable temperature:-30℃ to 200℃. The products are suitable for non-corrosive and corrosive gas, fluid, semi-fluid, solid, powder and other medium in HVAC, fire control, water conservancy project, water supply and drainage in urban, electric powder, petroleum, chemical industry, and so on.

Price Advantage: Our price is competitive because we process valve parts by ourselves.

We think “Customer satisfaction is our ultimate goal.” Depending on our advanced technology, complete quality control and good reputation, we will offer more high-quality valve products.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for Super Purchasing For Ss 304 Butterfly Valve - NBR Seat Flange Butterfly Valve – Zhongfa , The product will supply to all over the world, such as: Riyadh, El Salvador, Poland, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.