Butterfly valves are important components for controlling pipeline flow in various industries. Among the different types available, wafer and flange butterfly valves and single-flange butterfly valves stand out for their unique features and applications. In this comparative analysis, we will explore the design, functionality, advantages, and limitations of these three types to understand their suitability in different scenarios.

Note: Here we refer to the Centerline Valve, Concentric Valve.

ONE. Introduction

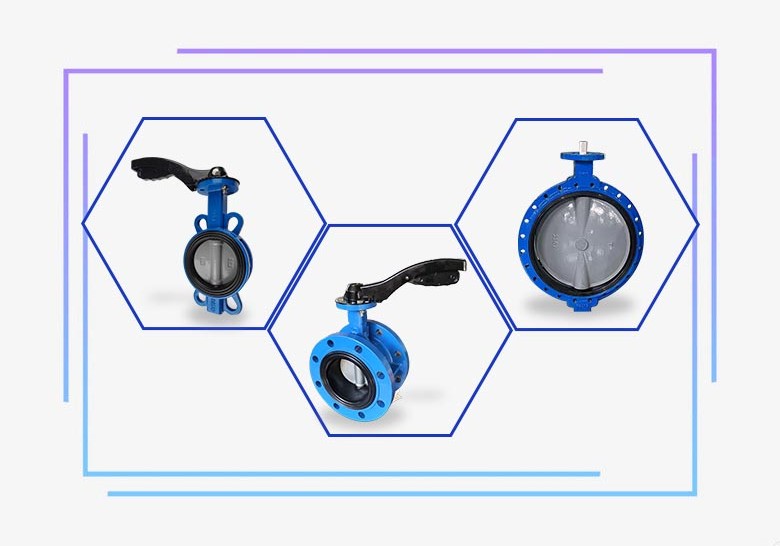

1. What is a wafer butterfly valve

Wafer Butterfly Valve: This type of valve is designed to be installed between two pipe flanges, usually a wafer flange. It has a slim profile with a valve plate that rotates on a shaft to control flow.

Advantages of wafer butterfly valve:

· The wafer-type butterfly valve has a short structure length, which means it is a thin structure, which makes it very suitable for environments with limited space.

· They provide two-way, tight closure and are suitable for systems with low to medium pressure requirements.

· The main advantage of the wafer butterfly valve is its compact design.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

2. What is flange butterfly valve

Flange butterfly valve: The flange butterfly valve has integral flanges on both sides and can be directly bolted between the flanges in the pipeline. Compared to pinch valves, they have a longer construction length.

Advantages of flange butterfly valve:

· The flange butterfly valve has a flange end that is directly bolted to the pipe flange. This design increases robustness and stability, making it suitable for high-voltage applications where safe connections are critical.

· Flange butterfly valves are also easier to install and disassemble, thus simplifying maintenance and saving costs.

· The flange butterfly valve can be installed at the end of the pipeline and used as an end valve.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

3.What is a single flange butterfly valve

The structure of the single flange butterfly valve is that there is a single flange in the longitudinal middle of the valve body, which needs to be fixed on the flange of the pipe with long bolts.

Advantages of single flange butterfly valve:

· It has the structural length of a clamped butterfly valve and occupies a small area.

· The firm connection characteristics are similar to those of flange butterfly valves.

· Suitable for medium and low pressure systems.

TWO. the difference

1. Connection standards:

a) Wafer butterfly valve: This valve is generally multi-connection standard and can be compatible with DIN PN6/PN10/PN16, ASME CL150, JIS 5K/10K, etc.

b) Flange butterfly valve: generally a single standard connection. Only use corresponding standard flange connections.

c) Single flange butterfly valve: generally also has a single standard connection.

2. Size range

a) Wafer butterfly valve: DN15-DN2000.

b) Flange butterfly valve: DN40-DN3000.

c) Single flange butterfly valve: DN700-DN1000.

3. Installation:

a) Installation of wafer butterfly valves:

Installation is relatively simple as they can be sandwiched between two flanges using 4 long stud bolts. Bolts pass through the flange and valve body, this setup allows for quick installation and removal.

b) Installation of flange butterfly valve:

Since there are integral flanges on both sides, flange valves are larger and require more space. They are fixed directly to the pipe flange with short studs.

c) Installation of single flange butterfly valve:

requires long double-headed bolts sandwiched between the two flanges of the pipe. The number of bolts required is shown in the table below.

| DN700 | DN750 | DN800 | DN900 | DN1000 |

| 20 | 28 | 20 | 24 | 24 |

4. Cost:

a) Wafer butterfly valve: Compared with flange valves, wafer valves are usually more cost-effective. Their short construction length requires less material and requires only four bolts, thus reducing manufacturing and installation costs.

b) Flange Butterfly Valve: Flange valves tend to be more expensive due to their solid construction and integral flange. The bolts and installation required for flange connections result in higher costs.

c) Single flange butterfly valve:

The single-flange butterfly valve has one less flange than the double-flange butterfly valve, and the installation is simpler than the double-flange butterfly valve, so the price is in the middle.

5. Pressure level:

a) Wafer butterfly valve: Compared with flange valve, the applicable pressure level of wafer butterfly valve is lower. They are suitable for low voltage PN6-PN16 applications.

b) Flange butterfly valve: Due to its solid structure and integral flange, the flange valve is suitable for higher pressure levels, PN6-PN25, (hard-sealed butterfly valves can reach PN64 or higher).

c) Single flange butterfly valve: between wafer butterfly valve and flange butterfly valve, suitable for PN6-PN20 applications.

6.Application:

a) Wafer Butterfly Valve: Commonly used in HVAC systems, water treatment plants and low pressure industrial applications where space is limited and cost effectiveness is critical. For use in piping systems where space is limited and low pressure drops are acceptable. They provide fast, efficient flow control at a lower cost than flanged valves.

b) Flange butterfly valve: Flange valves are used in industries such as oil and gas, chemical processing and power generation, where higher pressure levels and excellent sealing performance are crucial. Because flange butterfly valves can deliver higher pressure levels and better sealing and stronger connections. And the flange butterfly valve can be installed at the end of the pipeline.

c) Single flange butterfly valve:

Single flange butterfly valves are commonly used in urban water supply systems, industrial systems such as chemicals, petroleum products and industrial wastewater, regulating heating or cooling water in HVAC systems, sewage treatment, food and beverage industries and other fields.

THREE. in conclusion:

Wafer butterfly valves, flange butterfly valves and single flange butterfly valves all have unique advantages and are suitable for different applications. Wafer butterfly valves are favored for their short structural length, compact design, high cost performance and easy installation. Single flange butterfly valves are also ideal for medium and low pressure systems with limited space due to their short structure. Flanged valves, on the other hand, excel in high-pressure applications that require excellent sealing performance and rugged construction, but are more costly.

In short, if the pipe clearance is limited and the pressure is low pressure DN≤2000 system, you can choose a wafer butterfly valve;

If the pipe clearance is limited and the pressure is medium or low pressure, 700≤DN≤1000, you can choose a single flange butterfly valve;

If the pipe clearance is sufficient and the pressure is medium or low pressure DN≤3000 system, you can choose flange butterfly valve.