Wholesale Water Main Gate Valve - DI PN10/16 Class150 Lug Knife Gate Valve – Zhongfa

Wholesale Water Main Gate Valve - DI PN10/16 Class150 Lug Knife Gate Valve – Zhongfa Detail:

Product Detail

| Size & Pressure Rating & Standard | |

| Size | DN40-DN2000 |

| Pressure Rating | DN50-100 PN16 DN150-200 PN10 DN250-400 PN7 DN450-600 PN5 DN650-750 PN4 DN800-900 PN3 DN1000 PN2 |

| Design Standard | JB/T8691-2013 |

| Flange Standard | GB/T15188.2-94 chart6-7 |

| Test Standard | GB/T13927-2008 |

| Material | |

| Body | Ductile iron; WCB; CF8; CF8M; 2205; 2507 |

| Disc | SS304; SS316; 2205; 2507; 1.4529 |

| Stem/Shaft | SS410/420/416; SS431; SS304; Monel |

| Seat | Stainless Steel+STL EPDM (120°C) /Viton(200°C)/PTFE(200°C) /NBR(90°C) |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Gear Box, Electric Actuator, Pneumatic Actuator |

Product Display

Product Advantage

Standard AISI304 or 316 stainless steel gate is grinded and polished smoothly as mirror, which can effectively avoid damage of packing and seat through opening or closing and make a greater seal. The bottom of the gate edge is machined to a bevel, so that it cuts through the solids for a tighter seal in closed position. A knife protector can be provided for additional protection against dust.

There are 3 features as below:

1. Standard seat NBR, EPDM, also available in PTFE, Viton, Silicone etc. Unique design that mechanically locks the seal in the internal of valve body with a stainless steel retainer ring. Normally it is unidirectional seal design, and bidirectional seal as requested.

2. Several layers of braided packing with an easy access packing gland ensuring a tight seal. Available in a range of materials: Graphite, PTFE, PTFE+KEVLAR etc.

3. The guide block on the valve body makes the gate move correctly, and the extrusion block ensures the effective sealing of the gate.

ZFA Valve strictly execute API598 standard, we do both side pressure testing for all the valve 100%, guarantee deliver 100% quality valves to our customers.

The valve body adopt GB standard material, there’re total 15 process from iron to valve body.

The quality inspection from the blank to the finished product is 100% guaranteed.

Hot Selling Products

5k 10k Wafer Butterfly Valve

Dual Plate Check Valve

Non-rising Stem Gate Valve

Rubber Flap Check Valve

Lug Butterfly Valve

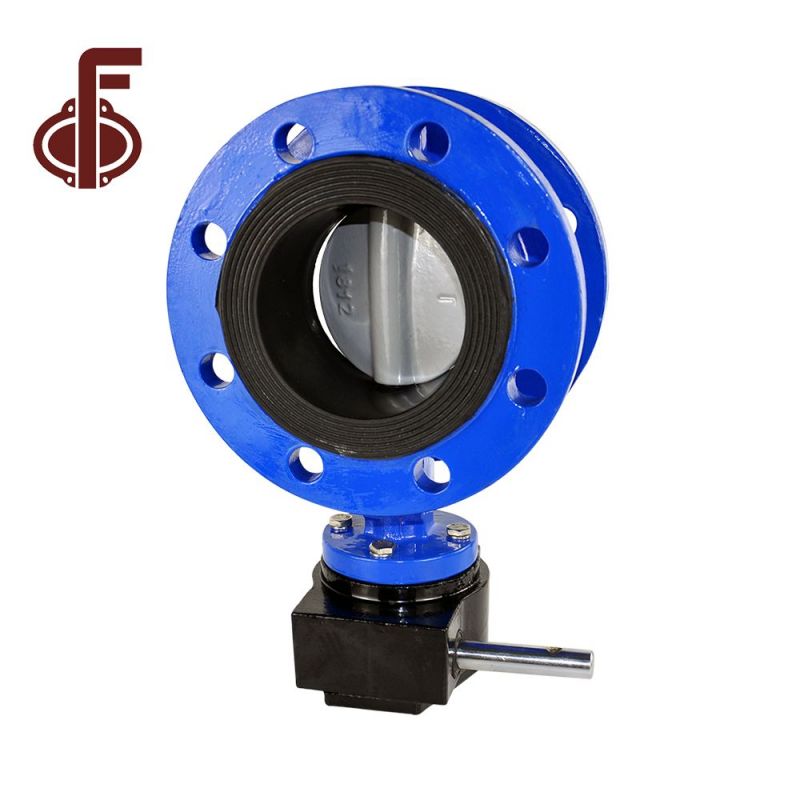

Flange Butterfly Valve

Knife Gate Valve

Welded Ball Valve

Y Strainer

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for Wholesale Water Main Gate Valve - DI PN10/16 Class150 Lug Knife Gate Valve – Zhongfa , The product will supply to all over the world, such as: Seattle, Indonesia, Italy, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!